Despite my experiments below being rather basic, I’d recommend returning bindings to G3. Consider below to be proof-of-concept and informative in nature. Also, any work such as this done on G3 ski bindings utterly and completely voids any sort of warranty.

Assuming the problem G3 alludes to in this case is the front pair of screws on the rear ION binding unit being improperly tightened or poorly threadlocked (or both), a fix I could do on my workbench seemed possible. (Note, it’s entirely possible that the screws in the warranty return G3 bindings are defective, yet another reason to be sure to return your bindings to the company if bindings have serial numbers that qualify.)

First, caveats and overall notes:

1.) I determined if my bindings bindings qualified for the recall, some did. That’s the ones I experimented with.

2.) This procedure is so quick it doesn’t really matter if it’s done with an extra screw or two, so I did all the screws in all my questionable bindings.

3.) Crux for me was to tighten “just enough” which in this case is minimal as these are soft stainless steel screws, 3 millimeter tiny diameter only engaging what appears to be at most 6 threads (and probably fewer). Using a downsized torque wrench would be best. I have a good feel for this kind of small parts assembly, that’s a plus. I found that grabbing the screw driver with only my thumb and opposing pinky finger, or pinky and ring finger, made a sort of “slip clutch” that guarded against over torquing. G3 specified tightening torque is 8inlb (0.9Nm). I tested my intuitive tightening torque and I was using close to that.

4.) I did one screw at a time, keeps it simple.

First, the binding heel housing is removed from the center turret. Video from G3 below animates the procedure. Quite simple, and what you need to do if you’re returning your bindings to G3.

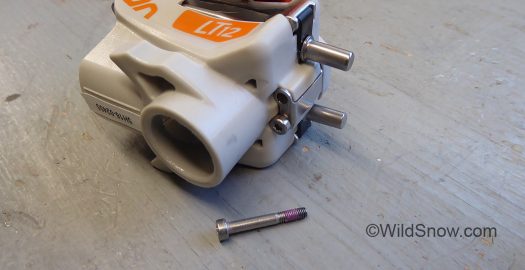

Before removing screws as shown, I adjusted the upward (vertical) release tension to a minimal setting. This places less upward internal pressure on the top plate. I removed and renewed ONE SCREW AT A TIME, to avoid turning this simple project into complex re-assembly.

I made this ‘G3 Screw Tool’ by heating and bending a torx 1.0 screwdriver, works nicely for checking screw tightness and will entirely remove screws for renewal of thread locker. Entirely removing heel unit from center turret makes the process easier.

Evidence of thread locker that perhaps is not as effective as one would like. I cleaned the screws by soaking for a few minutes in a cap full of lacquer thinner. In the case of using something like Loctite 242, a few challenges rise. Firstly, while I don’t believe 242 hurts this type of plastic (and did experiment with it), it’s said that Loctite damages some plastics. Moreover, stainless steel doesn’t respond to anaerobic thread lockers as it should, without a primer. But how will I get primer inside the heel housing screw hole without dousing it on other binding mechanicals? No way. So at this time I’m using JB Kiwk epoxy for threadlocker (see below).

I cleaned the screws by soaking for a few minutes in a cap full of lacquer thinner then wiping and air drying. Again, I’m doing this one screw at a time to avoid unnecessary disassembly of the binding.

I experimented with a variety of thread lockers, including Loctite 271. I was not happy with the Loctite, while regular superglue seemed to be adequate while still not locking the threads as much as I’d like. After testing, I’m of the opinion that a tiny dab of JB 2 part epoxy (e.g., JB-Kwik) on the threads does an even better job of thread locking, while still being reversible.

As mentioned above, when replacing screw it’s necessary to tighten it quite carefully and gently. If the threads or screw socket head are damaged, the binding is entirely dumpsterized. In the interest of science, I tested over-tightening on a demo binding that G3 kindly provided for the WildSnow Museum. Before I could strip the screws, I blew out the socket head due to it being soft stainless steel. This went way past “gentle tightening.” As I did the screws one-at-a-time, I marked the heads with a black Sharpie so it’s obvious what’s completed.

Notes: Field tightening of these screws requires either a custom made right-angle star-drive 1.0, or else the ability to remove heel unit from the turret. Doing so only requires a pozidrive screwdriver, but taking bindings apart is not exactly wonderful in the middle of a ski descent. Instead, perhaps check screw tightness at home. Key issue for me, as mentioned above, was to avoid over-tightening the screws. I’ve got a lot of tools, but lack a smaller torque wrench. Ordered one yesterday. Hand tightening with an experienced touch seemed fine but accuracy is good.

Just heard from G3, specified torque (via T10 Torx driver) 8inlb (0.9Nm).

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.