For more, check out Marker’s Kingpin website.

The King in full touring mode, lift engaged. Heel flat on ski is available and the two lifts heights are similar to most other tech bindings.

Synopsis: I’m impressed. After about three years of secret development, Marker releases a “pintech” modified tech binding with alpine-like elasticity and step-in comfort. The Kingpin binding toe unit is somewhat similar to other tech bindings, but boasts three pairs of springs (the Six Pack!) that are said to offer better “energy absorption.”

Heel unit is the big change, Kingpin operates without the “pins” all other tech bindings on the current market insert in your boot heel for alpine (downhill) mode. Instead, the heel operates as a virtual combination of alpine binding toes and heels. In terms of how it clamps your boot to the ski, it’s an over-center pivot lever that snaps down on your boot heel when you step in — pretty much identical to most alpine bindings. In terms of lateral release, the heel opens to the side, similar to alpine toe jaws (with a “second stage” lateral release happening as the toe wings open, as with most tech bindings).

Fancy doodads such as roller bearings on the heel cup and a beefy AFD on the brake actuator pad are intended to reduce the friction problems created by rubber soled or dirty boots — as well as providing a general reduction in friction overall. A large vertical release spring that’s reminiscent of the Marker Tour F10 and F12 models provides that ever desirable and somewhat rare vertical elasticity and travel in a tech binding. In this case a claimed 16 mm of vertical travel, which is several times the vertical heel release travel of most tech bindings.

Claim by Marker is that Kingpin is the quiver of one and will function equally as well on/off the resort, in aggressive skiing or mellow touring. Word is that you do NOT have to lock the toe for fear of accidental release during aggressive skiing (sometimes a concern with many other tech binding offerings). A viable width selection of ski crampons and brakes rounds out this tour-de-force.

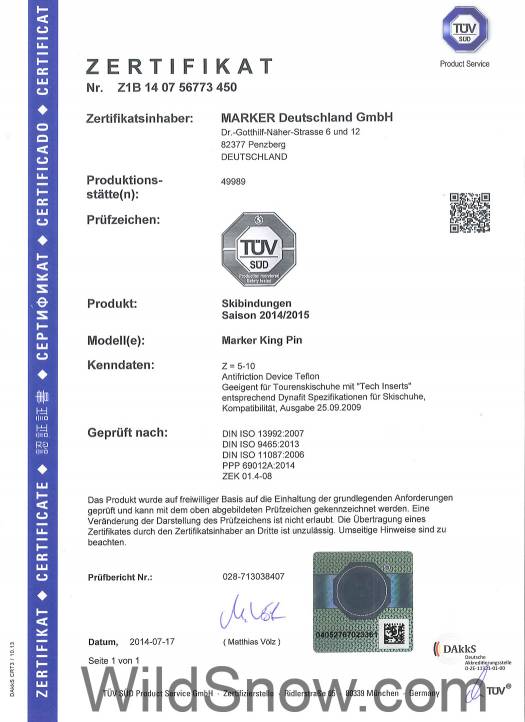

Real life advantages? While the Kingpin weighs a bit more than what could be considered equivalent competitors, it does appear to offer the retention and shock absorption of a full-on alpine binding, as well as offering easy operation. Overall, it is very “put together” in appearance and during my on-snow testing performed well. Importantly, or not (depending on your views) it has TUV certification to the appropriate DIN/ISO standards — the first tech binding to achieve this as far as I know and proved by the certificate in images below (dated July 17, 2014).

I’m writing this post while still in Chile at the Marker Kingpin binding introduction event. While I suppose they could be squirting some kind of brainwashing gas into the air ducts here at Rocanegra Mountain Lodge, that doesn’t appear to be the case. Instead, I’ve been on-snow with the Kingpin for several days of real ski touring that included excellent testing such as skiing icy snow as well as walking in areas that required many cycles of clipping and removing bindings. Overall, the Kingpin worked.

Sure, I’d perhaps choose something lighter for core touring in my home range, but this really does appear to be a binding you could travel the world with and use for everything from a day of blasting the pists of Sun Valley to slogging the passes of the Silvretta Traverse. (Kingpin only weighs a ‘chocolate bar’ more than competitor equivalent in a ‘tech freeride binding,’ yet is quite a bit heavier at 650 grams (no brake) than super-light options — which of course leads me to suspect Marker probably has some sort of superlight version in the works.)

Aaron Provine of Backcountry.com tests Kingpin in Chile a few days ago. I got the impression you’ll be able to purchase Kingpin at the Gearking, though quantities will be limited until 2015/2016.

Consumer use will of course tell the tale. To that end Marker will do a limited retail release of Kingpin beginning early this winter. Full retail will begin for winter of 2015/2016. Please see below for details and images, and while we did ski on the binding quite a bit down here in the land where North is South, please don’t consider this a full review or endorsement. It’s just a thorough first-look at what appears to be something very interesting and cool for the sport of alpine ski touring, or if you like different nomenclature, freeride touring.

The elusive Kingpin will be available in what could be called 5 versions, shown here is one binding with brake and one without. One version will have 5-10 DIN and one will have 6-13, a rental-demo version rounds out the selection. Note that creating the brakeless version of either DIN flavor will require buying the brakeless heel pad as a accessory, all bindings will be sold with brakes.

Toe unit boasting the ‘6-pack’ springs, available crampon mounts in what appears to be a strong slot. During my test days I experimented with not locking the toe during touring (desirable for travel while exposed to avalanche hazard), retention was average to above. I threw a shoe while doing an aggressive uphill kick turn, but otherwise toured for quite a while without ejecting.

Toe lock lever is similar to most other tech bindings. It’s long and easy to work even with small hands. As mentioned elsewhere here, you can exit the binding by pressing down on the toe lever, or opening the heel as with a normal alpine binding and twisting out of the toe, thus pre-cocking the heel for later use in downhill mode.

Step-in guides work by forcing you to position your toe as you step in, are adjustable but not easy to remove. Questions will probably come up about this concept as intellectual property or patent held by others who had this idea first, word I got was that since these guides don’t fold down they’re different enough from other ideas. Final reality of that will I’m sure get sorted out if not clear already. Interestingly, the small metal tabs of the Kingpin guides actually help smooth out release by forcing the boot into a more circular motion as the toe rotates out of the binding. Who knew.

Another view of the step-in guides. Note that all the gold anodized aluminum parts are hot-forged by DMM in Wales, esteemed maker of aluminum climbing gear. Idea of course being if you can trust DMM carabiners, perhaps this is a binding that won’t shed bits and pieces of aluminum over your favorite ski mountain.

6 to 13 DIN version has confidence inspiring black springs in the 6-pack. I’m assuming this is not a gimmick, and that to get stronger toe retention with the normal sized “tech” springs adding another set was the solution. Interestingly, the technical team guys told me they did extensive development on the concept of a rotating toe unit like the main competitor is using to a greater extent this coming season. I think that conflict in design philosophy will result in some interesting bench testing — as well as perhaps a brewing battle as to what the best design is for the tech binding archetype.

Another view, the toe locks for touring as with most other tech bindings. This is the 5-10 DIN version with silver colored springs.

Ta da, the complex engineering of Kingpin heel unit is reminiscent of something you’d see in aeronautics. Heel shown here is in rotation to demonstrate how it effectuates lateral release. To be fair, other brands are getting to this level of materials engineering as well, but for a first time offering in the tech binding arena to be this sophisticated is as delightful as finding a new pastry in Vienna, or perhaps Garmisch? The question is of course, as with pastries, is the look merely decorative or does it have flavor? In this case, we think tasty.

Looking at heel unit from rear, showing lateral release setting indicator. Don’t over-think how this works, you get in and out just like an alpine binding, though you can exit by clicking out of the toe with a ski pole press as with most other tech bindings. Big difference from most alpine bindings is the heel rotates to provide side (lateral) release.

The million dollar question, how do you switch modes? As with a Marker frame touring binding such as Duke, you work this flipper which in turn slides the heel unit along a track. It’s quite simple, and can be done with the ski still attached to your foot (though that’s a bit awkward.) At one point I got some ice in the works and had to tap on the binding heel with my ski pole grip to get it moving, that’s one out of dozens of mode changes I did while testing. Getting techie, the mode change flipper is connected to the heel unit with a flat rigid “tape” made of carbon fiber combined with fiberglass. This is small and nearly hidden from view, but according to my contact on the development team was one of the most difficult parts of the binding to engineer and manufacture.

Better view of the mode flipper. It’s connected to the heel unit with a carbon fiber strip that runs through a track. Unlike many tech bindings, this is not designed for 100% operation with a ski pole though in a pinch (cold hands with big mittens) you could get it started with a ski pole tip inserted under the side, then continue the motion by pressing with your pole grip. In all, it’s super easy to grab the flipper with gloved hands. I never had a problem with it.

Once you slide the heel unit back for touring mode, you step down on the brake to clip it up for walking. The mechanism for this is simple, as shown in photo the brake arms clip over a small steel stud. Tolerances are critical here, damage to the brake arms or the introduction of dirt and grit could cause problems, but nothing you couldn’t do a temporary fix on. Of more concern is the brake sticking closed while in alpine mode, in extreme icing conditions here in Chile I did have that happen once, but I’ve seen the same problem with other bindings. The Marker guys did tell me they are still fine tuning the brake for final retail version. Judging from the rest of this project I’m thinking they’ll have it dialed well before zero day.

Viewed from above, in touring mode with heel flat on ski. Kingpin requires a DIN/ISO ski boot sole ledge at the rear, an adapter will be available for boots with shortened soles, as shown in this photo. The adapter is quite nice and might be a recommended add-on to reinforce any tech compatible boot.

Adapter is screwed on in place of standard tech fitting. In this case we didn’t insert the side screws because I’ll be converting back once I leave here. The adapter is backward compatible to other tech bindings and is super strong. Similar to other brand’s offering.

Low lift, touring mode, similar to other brands. I found the heel lifters to be a bit difficult to flip with a soft ski pole basket, perhaps I’d refine my technique with more days on the Kingpin.

Heel in alpine mode, the rollers are there because the unit rotates to the side for safety release, and friction is the enemy. To expound, due to these rollers actually containing ball bearings and the AFD being so beefy, the heel unit rotational spring loading can be more responsive and actually stronger for given DIN setting. That’s perhaps getting a bit too technical, in plain English it means Kingpin might truly have exceptional resistance to lateral pre-release.

Boot with regular DIN-ISO sole shape fits in Kingpin with no adapter. Length adjustment for boots is accomplished by rotating a pozi screw at rear of binding, typical system of other brands and models. When the adjustment screw is flush with housing, forward pressure is correct. Compensation for ski flex is built in and obviously works fine.

DIN/ISO certification to standard 13992 by TUV. I’ve got mixed feelings about this. On the one hand it does prove the binding behaves in certain ways. On the other hand, while TUV (he who certifies, otherwise known as a god) has a good set of tests for frame touring bindings, but I believe it’s still an open question as to how those tests and standards apply to a tech binding. My main theory about all this is that TUV needed time to learn about tech bindings and how to test for the 13992 and other standards in ways that didn’t automatically fail the binding. This process of development by TUV took decades, and perhaps came together when Marker and their main tech binding competitor began working with them — both in terms of politics but also technology. On the business economics side, it is huge to have a TUV certified binding that protects the maker as well as sellers from lawsuits, (at least to a greater degree than selling bindings that conform to no safety standards). On the other hand, much of the TUV certification spiel you will be hearing as the “DIN Wars” commence could simply be marketing spreech. Proof of concept will be if the TUV certified binding from any company truly is superior in some ways. We won’t know the answer to that until more consumer testing is completed on the various brands. Meanwhile, kudos to Marker for all they’ve accomplished. Beautiful engineering, stunning industrial design — Kingpin worked nearly flawlessly for our group of testers over the past few days in Chile.

Michael Buckers, one of a small group of technical staff who worked on the Kingpin project for about 3 years. Buckers is also a certified guide and holds a degree in biomechanics. He has a nice smile.

Metrics

Crampon widths: 90, 105, 120

Brakes retract nicely so they do a good job of covering a range of widths: 75/100 and 100/125

DIN (nice to be able to call it that): One model goes from 5 to 10, model with black toe springs adjusts from 6 to 13 — and yes Virginia the black toe springs are slightly stronger and everyone will of course want them.

Rolling deflection (cuff of boot moving to left and right): I did a comparative test using other ‘freeride’ tech bindings, and kingpin clearly has less deflection. Of course it’s an open question as to whether you want to be welded to your skis like some guy with a buzz stick had glued a steel shoe to your topskin. On the other hand, all too many touring bindings have been way too sloppy, so a tighter connection is a better trend.

Screw pattern: 38 mm width.

Adjustment tools: Pozi 3 does everything.

Boot length range: 25 mm (demo version available with super wide range as well as adjustable toe position. Looks really good.)

Weight with brake and screws: 730 grams, 25.75 ounces

(Reference, Dynafit Radical FT is 566 grams, 20 oz, though this is not an apples to apples comparo. Dynafit Beast might be a better comparo, but we don’t have retail production weight for the 2014/15 Beast models.)

Kingpin weight without brake: 650 grams

Notes

Who better to make the aluminum parts than a climbing gear company? After all, skiing dangerous terrain and depending on small tabs of aluminum for your life is no different than hanging from carabiner. To that end, all the gold anodized parts are hot forged by DMM of Wales. It’s said they’ve been making the best metal in the world since the Bronze Age.

The small tabs of the “step in guides” are indeed similar to a competitor binding, but they’re metal instead of plastic as well as being tiny. While they come pre-adjusted (and during our testing worked fine for most boots) they can be user adjusted to compensate for boot wear and such. Removal would entail grinding or otherwise cutting them off, as the back part is integrated with the springs. They do not retract when you click, as competitor does. I experimented with a boot and the tabs don’t block release function, which I found surprising.

The elephant in the room for new touring binding releases is always durability. Sadly. While the only true test of binding strength is to get it out into the retail wild, I should note that in our three days of touring here in Chile with about 20 people (60 user days) I didn’t see any problems. Marker guys have been here with several other groups, for a total user day count of over 300 days, and say that did not have one durability problem during that time.

Oh, and you asked what was it actually like to ski and walk on the Kingpin? Touring felt like most any tech binding. A little heavier than I’m used to and the toe of my non-standard TLT-6 boot bumps into the front lever a little earlier in the stride than some other brands and models. The binding was quiet and the heel lifters seemed solid. When skiing down I noticed how reactive my skis were due to the astoundingly solid connection between boot/binding/ski. I’m feeling it’s even stiffer laterally than a Duke. The marketing term for this sort of beef is “power,” and that might be valid for some of you, but in my own skiing I don’t feel the need for any more solid of a connection than I already get with the average tech binding. I do however want a binding with nearly no chance of pre-release when set to normal release values. In that, I’m optimistic Kingpin may deliver. This involves personal safety of all of us, and that’s huge. So whether your’e looking for power — or safety, Kingpin will be something for your attention.

Check out Part 2 of our Marker Kingpin coverage.

For details from the source, check out Marker’s Kingpin website.

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.