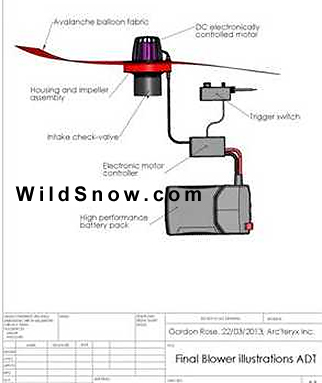

Arcteryx airbag fan system illustration from the PR.

Readers, you’ve been asking where Arcteryx fits into this whole fan based avy-airbag schema. For more clues, the software company Arcteryx is using to design their turbo had this to say in a press release back in April.

For some reason this never blipped our radar. We were probably basking in the spring sunshine up at WildSnow HQ. Better late than never.

My take on the Arcteryx fan airbag has always been to wonder how a company that pretty much just does textile engineering could enter such a high-tech minefield. Taking a fan based avalanche airbag to market is most certainly a daunting task. Not only does a project like this combine textiles with electrical and mechanical engineering, but you’re also up against a challenge in Europe in that to sell an airbag pack there you need it to be TUV certified. But apparently there is no set of standards for TUV to certify a fan based pack. A case of standards stifling life-saving innovation? We shall see what blips our radar on that one!

Press release follows, edited for brevity, see full press release.

ARC’TERYX turned to ADT to optimize the blower system on its evolutionary new airbag rescue system

LONDON, NEW YORK and VANCOUVER – April 10, 2013 – Advanced Design Technology (ADT), a global leader in the development of advanced turbomachinery design methods and the TURBOdesign Suite today announced that its customer, ARC’TERYX Equipment Inc. hired ADT to assist in the design of an evolutionary avalanche airbag backpack system… battery-powered electric motor that inflates airbags instead of relying on compressed gas cartridges or cylinders. ADT optimized the blower system.

“I was initially drawn to ADT when looking for software to use in designing the blower,” said Gordon Rose, senior industrial designer for ARC’TERYX. “But, after contacting ADT and discussing the complexity of the project, we decided a much better solution was to use ADT’s design expertise and have them optimize the blower system.”

ARC’TERYX worked with London-based ADT to engineer the new avalanche airbag backpack using three-dimensional (3D) inverse design methodology, which now enables engineers to specify the desired flow field (via blade loading) along with the total work required and automatically generate the geometry that produces that flow field. By specifying the blade loading, engineers have direct control over the 3D pressure and velocity distributions, which allows for direct control of the 3D flow field and an intuitive connection between the design input and the resulting performance. This change allowed the engineers to explore a large part of the design space and arrive at the resulting breakthrough design.

“Our… design optimization technology provides innovative solutions while reducing development time and costs,” said Professor Mehrdad Zangeneh, founder and managing director of ADT. “By using TURBOdesign1 on the ARC’TERYX avalanche airbag backpack air blower we could achieve their stringent requirements in terms of small size and high efficiency. Furthermore we could achieve a design which could meet contrasting requirements in terms of high pressure at initial deployment of the airbag and then high flow rate for rapidly filling up the bag.”

Previous WildSnow post about Arcteryx fan airbag patent.

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.