Part One, Epic Details of the Dynafit Radical Ski Touring Binding

Why TUV? Why do binding companies work hard to have their products certified by TUV to conform to standards such as DIN 13992? Established consumer standards tend to help more than they hinder. Dynafit (and any other binding company going for TUV) wants to do good by their consumers. But in my view, simple economics is also playing a big role in this issue, perhaps the biggest.

Ski shops have never liked selling non-certified tech bindings. The first company to have a tech binding certified by TUV to the DIN/ISO touring binding standard will sweep the retail market. This is axiomatic.

But will any TUV certification (to the existing standard) truly benefit the end user and be an ultimate improvement of the tech binding? Lovely if it happened — yet the results could be mixed.

TUV is the European outfit that certifies everything from baby bottle warmers to automobile tires, with “certification” meaning the items in question conform to some government standard (adding confusion, TUV can actually be paid to certify to your own standard, so beware of that when evaluating TUV certifications — e.g., even Dynafit bindings had a TUV stamp at one time.). Standards such as the DIN/ISO touring binding standard are well intentioned, but conversely it’s not unusual for such standards to stifle innovation because “out of box” thinking frequently doesn’t conform effectively to a standard. Most importantly, the existing DIN/ISO ski touring binding standard simply does not accommodate tech ski touring bindings.

In cases such as this, the solution is often a new standard.

Indeed, I’ve heard murmurs that a standard for “tech” ski touring bindings is being attempted. Perhaps DIN/ISO has that in the works to roll out soon, or TUV will simply certify to their own “standard.” But everything I’ve heard indicates that a tech binding standard is years down the line, and could be impossible due to the difficulty of agreements amongst industry principles (just imagine Italian guys from ATK, French guys from Plum, Germans from Salewa and Canadians from G3 in the same room trying to agree on a standard? Perhaps Canada could bail out Italy? And come to think of it, is the lack of an American tech binding indicative of our decline as a world power? BD, save us. And then there is Greece.)

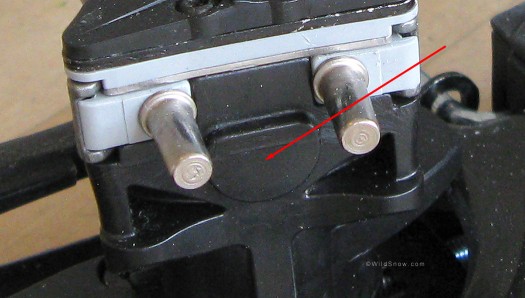

This mysterious bump on the heel unit of Dynafit Radical model series bindings is probably part of an ongoing process to build a binding that can receive TUV certification to the DIN/ISO ski touring binding standard. This is a good example of how such things end up being included for TUV, but in real life do nothing to help binding function, and in this case could even be detrimental to performance (by limiting amount boot can move between binding heel and toe unless complex and heavy mechanicals are added to the heel unit to allow it to slide for/aft to absorb pressure from boot heel).

More, a “tech” binding standard based on current designs is a bit ludicrous on the face of it. For example, when the tech binding was invented more than 30 years ago, some parts became the sizes and shape they did simply because of the drill bit that was handy, or the time and method it took to hand-make a part. To convert that to a “standard?” Unwise. If we want a tech binding standard it needs to be tech 2.0, engineered from the ground up: a frameless concept mated with boot fittings as existing tech binding are, but everything re-thought (including the boot). TUV baby bottle testers are not going to help with that process — only hinder it.

In the case of backcountry skiing bindings, we have DIN/ISO standard 13992 which is pretty much designed for frame/plate bindings. Standard 13992 has no provision for tech type bindings. None. Furthermore, once a DIN standard is promulgated, TUV engineers who have little to no knowledge of the practical side of ski touring my be in charge of developing testing methods, as well as interpreting the standard.

Result: Parameters such as weight and basic reliability get overshadowed by “features” such as brake AFDs for boots that, unlike alpine bindings, are suspended between toe and heel units and perhaps need little in the AFD department. Or weird and complex attempts to compensate for ski flex. Who knows what else.

The conclusion is obvious. Companies seem to have an incredibly difficult time improving the tech binding even without the involvement of TUV. Their efforts are admirable, and Dynafit’s efforts to help with heel lifter issues and release reliability are admirable.

But how successful are these efforts? They stutter. And if a binding company starts building in features to satisfy some faceless engineer at TUV, what on God’s snow white earth are we going to end up with? A binding that sells well at Sportler or REI, but no core skier of any intelligence will use?

Please don’t construe my rant as any accusation that Dynafit is a sellout. They are far from that, being managed by core skiers and providing what is easily the best complete line of ski touring gear out there. I know these guys, and can testify that we owe them huge for the amazing array of gear (both theirs and the competition they’ve energized) that makes our tours so fluid and fun. But a company has to survive financially. No, it’s not being a sellout to be a wise business person and direct your energy to financial success. If Dynafit needs REI and Sportler sales to survive, then so be it. Yet I think it’s obvious that focus on TUV certification could easily be problematic and should not be rushed. In the end, if Salewa/Dynafit’s energy is indeed going to producing a TUV certificable binding, I wish them the best on all fronts.

Luckily, Dynafit is covering all their bases and will continue to offer their non-TUV designs for some time yet (and that alone tends to validate the above points, does it not?).

Techincal note: Over the years, I’ve learned that one of the main sticking points with TUV certification of tech binding to the current DIN/ISO ski touring binding standard is provision for ski flex. As tech bindings currently function, the flexing of the ski changes the heel gap, which in turn changes the release values as well as possibly causing accidental release if the boot heel hits the binding heel unit. Keeping that in mind, keep your eye on binding developments.

Also, I have a solid insider source that tells me Plum is on the case with this as well, and has already tested and passed some variety of “standards” at TUV. Unknown at this time if they actually got certified to the DIN/ISO ski touring binding standard.

Other sources have told me that another sticking point for TUV is that they tend to consider the boot fittings as part of the binding, and thus any certification they do would need to be only for a certain brand or model of boots and specified that way; a difficult proposition.

You can bet there is going to be some smoke and mirrors with all this, as the race is on to see who can stick a TUV stamp on their products. Consumer beware, as always. If someone says their binding is “certified” you need to know to WHAT it is certified and by whom, otherwise you are listening to BS.

According to inside sources, getting a TUV certificate for a ski binding costs at least 15,000 euros per model, plus an annual fee of about 1,500 euros. The certificate expires after 5 years.

Again, your comments folks?

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.