While in Austria and Germany this past month I had the much appreciated opportunity to meet with the Dynafit engineers and top managers, purpose being to clarify what’s going on with problems they’ve had with the recently released Radical ski binding models. Most importantly, I wanted to take a positive view wherever possible and report on how the solutions are progressing, as Dynafit does take pride in their customer service, and by most accounts it is generally top notch. Part One of my take follows. Part Two will present my opinion about efforts at TUV DIN certification of tech binding.

First, to be fair to Dynafit one must take the large view of all this. While the physical cause of the Radical binding problems are factors such as materials defects and design flubs, the ROOT cause of the problems is the noble effort by Dynafit to IMPROVE the tech binding. Yes, other tech bindings now exist on the market. Yes, some may be quite durable. But such bindings are for the most part staying with what is now the amazingly functional but ancient design (now mostly out of patent) that was invented by mechanical genius Fritz Barthel in Austria nearly 30 years ago! Time for a few improvements? I’d think so.

For example, how about an easier heel lifter and one less prone to damage to the binding or the ski pole from over-levering? Or elimination of problems with the heel unit rotating accidentally while touring? And what about boot retention (pre-release prevention) while in downhill mode. Any way to improve that? And consider how much newbies (and even veterans) fiddle when attempting to click their boots in. Couldn’t we be nicer to them? For better or worse, Dynafit Radical has features that attempt to address all that and more. Indeed, if you take the problems and solutions mentioned below into consideration, you should be very happy with a pair of Radicals on your feet. Perhaps happier than you’d be with any other tech binding.

But yes Virginia, Dynafit’s effort to improve the Tech binding has not been without problems. Following is intended to clarify the situation, and offer a bit of “blogination” style opinion from yours truly:

Anti Rotation Pin Debacle

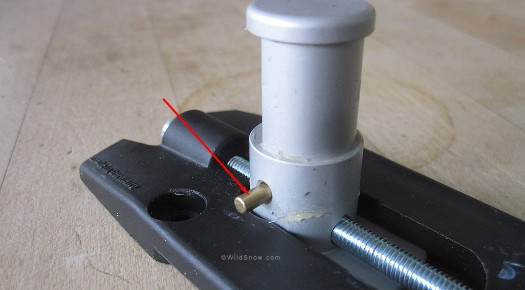

The pest that caused the biggest problem for the Radical is this tiny spring-loaded pin which rests in a hole in the heel spindle post. This is the original style pin; newer styles are designed to break before the housing blows out. We recommend not using any pin whatsoever with an external anti-rotation solution. Dynafit Radical bindings sold for the 2012-13 season have the pin removed and an anti rotation stopper installed at the factory.

As we’ve detailed in several previous posts, Radical series bindings (prior to 2012/13 retail season) have a tiny internal “pin” in the heel unit that prevents it from rotation past a certain point in the counterclockwise direction. Problem was, Dynafit designed the pin into the housing without any discernible effort to reinforce the housing. Result: damage to the housing that is sometimes quite severe.

During the 2011/12 season, Dynafit’s first solution to this was twofold. First, they changed the pin to one that breaks under heavy force to ostensibly prevent binding housing damage. Alternatively, you could take the pin out and run without it, or install either a Dynafit anti-rotation fitting on the brake retractor plate (available from dealers) or an aftermarket solution from Maruelli. In my opinion these solutions are adequate, and we here at WildSnow recommend. For the 2012/13 season all Radical bindings come with the pin removed as well as the external anti-rotation factory installed.

Running original versions of the Radical binding with the thicker pin may continue to work for some skiers, especially those smaller in stature with gentle technique. Nonetheless we recommend the above changes for anyone — especially if you ski tour far from trailheads, or expeditionary style where a broken binding could be life changing.

Maruelli aftermarket anti-twist solution for Dynafit Radical is also available in a version that doesn't require a brake for attachment, so it might be a good solution for the Radical Speed model.

Brake AFD Breakage.

Early AFDs on the Radical had the spring pop out, or the unit came apart entirely. Through several inline manufacturing changes Dynafit claims to have eliminated this problem. After a careful examination of the subtle changes Dynafit made to the AFD, I have no reason to doubt that. Consumer testing will of course have to prove it. This problem is a good example of doing something that was probably at least in part done for future attempts at TUV certification, yet created a binding that broke. (more in Part 2 on the TUV issue.)

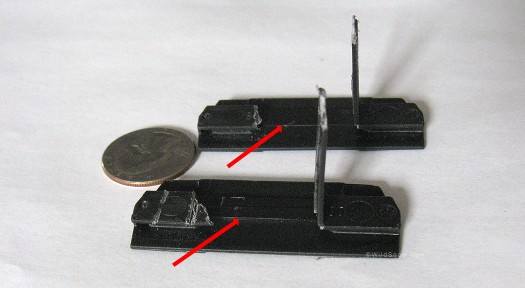

Dynafit engineers in Munich were kind enough to lay a pair of AFD on me. New version at bottom has a tiny rib (indicated by arrow) that helps keep the spring from popping out.

Brake AFD moving up-and-down and squeaking when touring with heel flat on ski

While this is mostly an aesthetic problem that perhaps most people don’t notice, after tens of thousands of strides something could wear out in the brake due to the movement. The situation is caused, again, by an attempt from Dynafit to improve on the design of existing Vertical model series bindings.

With the Vertical models, users would occasionally break off the tab (heel rest) on the heel unit housing your boot heel sits on when you are touring in the lowest heel position. This was caused by the tab simply not being strong enough, but also by the tab and brake parts having very little room for snow or ice when the user compressed everything together while switching to touring mode.

To allow room for ice and snow, Dynafit engineers added clearance to the brake retraction system, while also making the plastic heel rest slightly thicker. More, the new Radical brake with AFD is thicker than older models. Result is the brake sits higher when collapsed, and when you stride your boot heel hits the brake AFD just a few millimeters before your boot heel rests on the binding heel rest tab. In my view the Radical foot-flat-on-ski heel rest could have been strengthened without creating this situation, though I do agree a bit more clearance in the brake retraction system is probably a good thing. But again, did the solution create a problem? Jury is still out on this one, but pay attention to your Radical binding brakes if you do a lot of touring with heel flat on ski rather than up on any of the riser positions.

Heel Lifters Breaking Off

I’m told by Dynafit, and have this verified by independent sources, that this problem is actually a manufacturing defect (hydrogen embrittlement) that was simply one of those totally unpredictable occurrences that sometimes happen when you manufacture metal parts. (See official Dynafit take on this). I’m also told the actual number of defective heel units was very small, and that they’ve actually received many more broken Vertical model series heel units than those of the Radical.

All that is good, but the facts remain that 1.) Broken Verticals model heels are usually caused by human error: over leveraging with ski pole. 2.) Broken Radical heel is a manufacturing defect. 3.) Excuses about manufacturing defects aside, machinery we depend on for critical activities such as alpinism should, if possible, be engineered with redundancy for material defects such as hydrogen embrittlement, not to mention rigorous quality control. For example, why not make the whole Radical heel unit top plate as one monoblock machined or cast aluminum piece, such as competitors’ bindings? Instead, the actual metal part that holds the Radical heel lifter is incredibly minimal, and is asked to not only hold your weight, but your weight leveraged by how the heel lifter hangs forward from the heel unit. The forces this leverage creates are immense. Imagine your finger under the heel of a 200 lb human, stomping down from the height of say, 18 inches. Now add significant leverage to the force.

I don’t claim to be an engineer, but common sense sometimes seems to intrude. Yes, it could be said that building the Radical heel unit out of smaller and more elegant part is somehow progressive in comparison to competitors who use brute strength blocks of metal for strength. But then, sometimes the simplest solution is the best (though to be fair, those competitor bindings have been known to break as well).

How Do I know If My Radical Binding is the Latest?

The gorilla in the room with all this is how do you tell an upgraded binding from an older one, besides nearly microscopic examination or a consultation with the tech binding gurus at your local ski shop? The answer, according to Dynafit: From this date forward every binding that is purchased from your local shop or on-line has an upgraded pin, plus starting April 1st all Radical Bindings will be issued with the Dynafit designed Anti-Twist plate.

Whatever the case, mitigating factors exist. First, the rotation pin can easily be checked, removed, whatever (have a pro do this unless you know what you’re doing). Second, breakage of the heel unit lifter is/was actually quite rare, and most of the bindings out there are either upgraded or never had the problem in the first place. Third, if the AFD fails it’s not a deal breaker by any means, even if you’re on an expedition. Ditto for the brake movement.

Positive outlook is this: If you know your Radical bindings are from the latest manufacturing run, and have rotation pin removed or perhaps changed to external solution, you can confidently enjoy the binding for day trips and such without fear since no matter what happens you’ll probably get home. But due to uncertainty with exactly what bindings out in the wild have what improvements, for expeditionary use or core extreme skiing we still recommend the Vertical FT model, purchased with 110 mm brake and installed with Power Blocks (buy additional narrower brakes if needed). Once things have settled out and we see the above problems fade into the distance like Shane riding away never to return, we’ll change our recommendation. Sorry about that, but I simply can’t see any other way we can approach this stuff. (If you don’t know what I mean by Shane, do some research on the classic movie.)

Your comments oh esteemed readers?

Please see Part 2, The Move to TUV

Important, also see this post regarding Radical heel units blowing up due to weak screws and other factors.

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.