Next best thing to ski touring? Another factory post today — getting an inside look at where our tech gear comes from. In the case of La Sportiva, nestled at the feet of the Itailian Dolomite along the banks of the Rio Gambis, I gained entry to their brand new Innovation Center. Check it out.

Innovation center is an entirely new building. That’s myself and Sportive head guy Lorenzo Delladio. I’m told he’s the driving force behind this new facility.

The overarching idea here is that La Sportiva brings their previously disparate prototyping under one roof. Along with that, they moved much of their hand-labor intensive carbon fiber work to their own facility instead of a subcontractor foundry. Goals: better privacy for innovation (it’s said “you can’t keep a secret in Montebelluna, Italy”), and better quality for Stratos Cube carbon boot shells.

The structure includes a manufacturing space on the first floor, offices on second, and nice guest apartments on top.

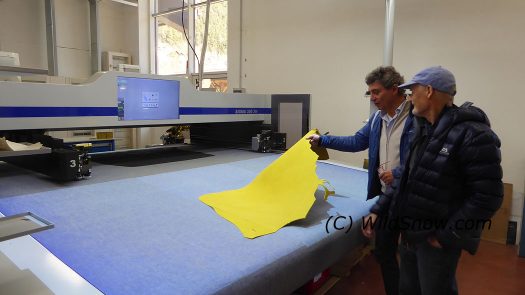

We walked to the Innovation Center through the factory. I’d blogged about this before, but a few photos are in order. This is the big computerized fabric cutting table, used for optimizing leather shoe and boot parts.

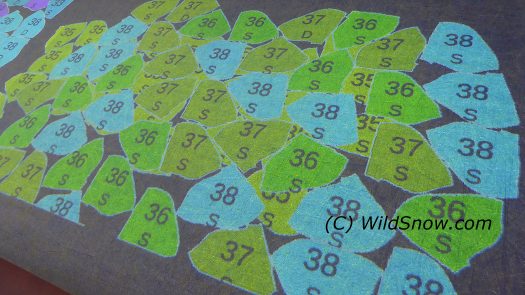

The cutter projects its cut pattern down on the table, this is the puzzle it comes up with for the most efficient material use.

Cutting leather the older fashioned way, with a press and ‘cookie cutter’ die. In both methods, human inspection of the material is key, but Lorenzo told me they’re trying to digitize the inspection process. Interestingly, he told me that despite their various forms of automation they don’t seem to be reducing their number of employees.

Downsized sewing center where they do prototypes and custom work. This guy is stitching a customized liner for a skimo racer, with a shimmed sole to avoid the heinous weight gain of using custom footbeds.

Over at the boot bench, this is one of the original tries at a Spectre boot shell shape, it was based on their mountaineering climbing boots.

Stratos sole installation. Lorenzo told me they don’t exactly have the highest profit margin on these: “If we marked these up as much as a usual product, they’d cost 5,000 euros!” My impression is they make Stratos for a lot of reasons, but not as a profit center.

Prepping for sole installation. I found this handwork process to be ironic in that the roots of footwear companies such as Sportiva involve boots and shoes that were at one time 100% hand made. What goes around comes around… I’m told the guy making the Stratos is a genius.

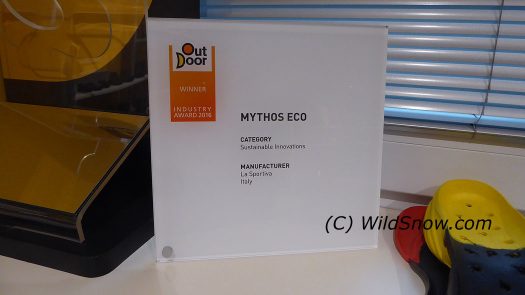

Circling back to La Sportiva bread and butter, beautiful climbing footwear. In this case the Mythos Eco, built in part from recycled factory scraps.

(This post is part of my continued, if staggered, reporting from the ISPO trade show and recent trip to the ski touring heartland of Tirol and Sud Tirol. )

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.