Ski touring binding companies sometimes tout their TUV certification to DIN/ISO standard 13992 for ski touring bindings, (9462:2014 is the alpine binding standard). What’s it all mean?

ISO/DIN standards for ski bindings are complex (to the layman) engineering documents that depend on foundational standards such as boot sole shapes. In my opinion they’re dated and meager, but necessary to a healthy ski equipment industry. A faustian bargain.

Through a process involving draft proposals and voting, industry representatives agree on a complex set of requirements for a given product. Result is a DIN/ISO standard. Both DIN and ISO are organizations that produce engineering standards, with ISO tending to administer/document the standard worldwide. In our writing below, we’ll refer to the standard as ISO.

More than 19,000 ISO standards apply to things we use in modern everyday life — everything from medical equipment to ski bindings. To get certified, the product is tested for those standards (in the case of ski bindings) by TUV. In our view, the main purpose of all this is so retailers can pay less for liability insurance. More about ISO.

What is TUV? A for-profit testing company that certifies products according to various standards. See our extensive coverage.

Does a TUV certification for ISO 13992 directly benefit the consumer by insuring your ski touring (backcountry; randonnee) bindings have a basic and functional level of safety and performance?

The answer to the consumer safety and performance question is mixed, with the caveat being a ski binding could be made that is safer than the certification requires, or more heinously, could be safer yet non-certifiable due to an odd configuration the standardized tests are not designed for (this is the ongoing problem with tech binding innovation). Thus, consider below to be somewhat of an endorsement of the ISO standard 13992, but not a blanket approval of it being the end-all be-all in knowing a binding is the best. In fact, I’ll be the first to state that plenty of ski touring bindings, perhaps the majority, as of 2022 do NOT bother paying for testing to the 13992 standard. Basically, it’s proved to be a dated pain-in-the-rear that often appears to be more of a marketing ploy than anything concrete.

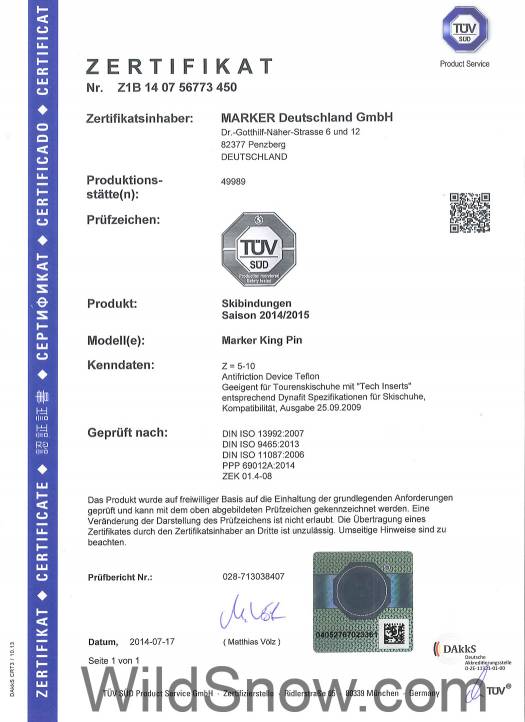

Marker Kingpin ISO certification certificate from TUV. This states that the certification is based on “tech inserts” defined by a specification for Dynafit ski boot compatibility. From insider sources, we know that a few dedicated engineers and industry people worked hard (thanks!) on providing TUV with a “draft” standard, so TUV could work with a definition of properly shaped and located tech fittings. Prior to that, the situation was problematic as any standard is based on other foundational standards. Since the “tech inserts” specification is not an official standard, the certification document has to note such. Click to enlarge.

Regarding tech bindings, the elephant in the room here is I’m told TUV does test with a “standardized” tech fitting equipped boot sole (as well as ISO having a draft standard in development for tech binding boot fittings).

Additionally, the use of “Dynafit” fittings may be noted on the TUV certification as a sort of caveat. This is a huge issue, as your boot fittings might not be the same as those used for the testing. Solution comes down to the consumer and retailer. If the boot releases smoothly during bench testing, my guess is you’re using fittings similar enough to those used in the cert tests. Thus, rest easy but know that in the end your own release checks are just as important as any stamps, stickers, editor’s choices or DINISO/TUV/youracronymhere kudos. In other words, test or yourself, or depend on a trusted shop technician, or both, then take a sharpie and write 13992 on the binding.

The bulk of both the alpine and touring binding standards involve safety (both are nearly identical), specifically how the release functions under various tortures. The testing also involves an on-snow evaluation.

The instrumentation safety tests are what’s important as any binding eventually gets tested “on-snow” by us all — the proverbial consumer testing cycle that’s incredibly annoying but apparently essential. Perhaps ISO should have a section in their standards document that details how consumer testing should be done: 1.)buy binding, 2.)go ski, 3.)break binding, 4.)wait for inline upgrade, 5.)get frustrated! You know the drill. We’ve been doing it for decades.

Below is an unofficial outline of the tests I sourced by viewing various documents. Know the specifications are complex engineering diatribes that refer to other standards (such as boot sole shapes) as well as clarifying definitions. Those things are beyond the scope of what we’re covering here, the idea being a simplified overview and comparison of the touring binding standard to the alpine binding standard.

1. In both alpine and ski touring binding standards, the testing procedure begins with six bindings.

2. Four out of the six bindings are randomly chosen and tested for reproducibility of release values, as well as the accuracy of the release setting scale on the binding conforming to lateral (side) and vertical (upward) torque standards in the ISO specifications. When set to the same DIN number, upward and side release have to be within 10% of each other, as well as being within 10% of the standard value. The over-arching thing here is that WHEN YOU SET YOUR BINDING DIN NUMBERS AT HOME, YOU COULD BE APPROX 1 FULL NUMBER DIFFERENT BETWEEN BINDINGS, AS WELL AS NEARLY A FULL NUMBER DIFFERENT OVERALL. IN OTHER WORDS, A BINDING SET ON 9 COULD ACTUALLY BE ABOUT 8 OR 10. This alone could be the reason so many skiers have given up on any sort of meaningful setting of their binding release values, and just “crank it up.”

This appears to be the same for both alpine and touring binding standards. (The weird part of this is that if the 4 chosen bindings don’t average out to compliance, the tester can swap in the remaining two test bindings and try again. That seems too forgiving.)

3. One binding is tested for consistency of safety release as the ski flexes. 20% deviation is allowed for side release, 15% deviation for vertical. I’m told this is the test many tech bindings can’t pass (due to the heel gap changing while the ski flexes), and why the tech binding heel designs have undergone so many changes. Same test is applied to alpine bindings.

Example excerpt from ISO standard depicting test for influence of roll loading. (Excerpted under fair use doctrine to illustrate commentary and criticism.)

4. Using a standardized test load, one binding is tested for influence of forward body lean on the release settings; upward and side release have to remain with 10% of each other; a deviation of 35% is allowed in both standards.

5. Backward lean influence on release values. 25% deviation allowed with both standards, same loads. I’m told this is one of the tests most tech bindings have trouble passing unless they’re carefully designed. Does passing or failing this have any real-world application? I’d say yes, as in many ski falls — and recoveries — the “backseat” position is the dominant state of affairs. If the binding release values lower radically in a recovery of a possible rearward fall — instant pre release. Conversely, if the values get radically higher and you take a rearward fall needing safety release, can you afford a new ACL?

6. One binding is tested for influence of roll loading, (as if cuff of boot is pressed to left or right). 20% deviation in release values allowed with both standards, same loads.

7. Next is how axial force changes release values (axial force meaning the boot pressing forward along the axis of the ski). Example, if your ski tip hit a solid pile of dense snow and caused an overall deceleration of your speed, your boot might exert forward axial force on the binding toe. Both alpine and touring standards allow 15% mean deviation in release values, same testing force loads.

Axial force of boot on binding heel and toe units. ISO 13992 only specifies testing in forward direction. Click to enlarge.

While this part of the standard might sound inconsequential, it demonstrates the lack of consideration ISO 13992 has for pintech tech bindings. Reason, some tech bindings are sensitive to rearward axial loading, which could be a poorly understood yet real contributor to unintended release. (Example, doing a falling leaf sideslip in a couloir, you’re moving backwards and your ski tail impacts a rock or chunk of ice.)

8. A test binding is chilled to -20 centigrade; 35% deviation allowed for both touring and alpine.

9. The binding is “iced” using several different methods of coating with ice; mean deviation allowed is somewhere around 35% for both alpine and touring (my source material is unclear). Icing is bad. We all know that. Clean iced bindings before skiing.

9. A shim is placed under the front part of the boot sole to simulate snow packing; around 35% deviation allowed with both touring and alpine standards. It is unclear how this test is configured to deal with pintech bindings that hold boot at various heights above ski, and moreover have optional configuration with and without a ski brake actuator pad under the heel of the boot. In truth, seems like a rather ridiculous part of the standard. Clean your bindings and boots before entry; that’s the actual real-life standard.

What is more, speaking of brakes, it is my understanding that DIN/ISO requires ski brakes that can not be manually locked to inactive status while skiing downhill. This is serious, because to the best of my knowledge not one tech binding company has ever made a 100% reliable automatic brake that retracts and deploys in relation to rotation of the heel unit between downhill and uphill modes. Instead, the most useful and consumer friendly tech binding ski brakes are manually switched between locked and unlocked modes. Correct me if I’m wrong.

10. Vibration and shock. The skis are tumbled in a drum and one is dropped 5 times, bam bam. 15% mean deviation from standard release values is allowed, apparently 10% for adult alpine bindings, though my interpretation could be off and both standards are the same. This should be a low number, as ski bindings are always undergoing vibration and shock.

11. ENERGY ABSORPTION! Also known as “recentering.” In my opinion, beyond verification of release forces this is one of the most important parts of the standard. Sadly, it appears to me in evaluating both alpine and touring binding standards that this requirement is minimal and doesn’t reflect current state-of-art in either touring or alpine bindings.

First, I take issue with the term “absorption” (disclaimer, I only took high school physics and am not an engineer). If the binding is returning you to center under spring tension it is storing energy, not absorbing it. Perhaps that’s just cosmetic semantics. The underlying item here is that after force is applied and you don’t get a release, the binding needs to get your boot back in position in the binding, within <>2 mm of original position (in both standards, same amount of absorbed energy). You can evaluate recentering with simple bench tests — but without test machinery you can not accurately evaluate energy absorption/storage, you can only go so far as the tactile feel of the binding as you bench test or ski on it.

Alpine standard states “The binding, after absorbing the required energy, shall return the test sole quickly to within <>2 mm of its original position…the quasi-static method [of testing] does not allow a prediction of the dynamic behavior of the binding in all circumstances but it does represent…evaluation of this behavior”

12. The binding is checked for “lateral release under impact loading.” I’ve seen the rig for this. It’s essentially a striking weight of given mass on an arm that swings down a given distance. The documents call it a “pendulum.” The boot is mounted rigidly and the striker hits the ski from the side. Idea here is that the binding can absorb a certain amount of force from the hit before releasing. Both alpine and touring standards for this are the same. Interestingly, this test is defined by another entire standard (probably because it’s fairly complex), ISO 9465:2012. While titled “Alpine ski-bindings,” 9464 is also used to configure this test for ski touring bindings.

According to an insider engineer I spoke with, this is actually a better test of energy absorption/storage than the return-to-center testing. Moreover, the engineer clarified that with springs and no damping, the binding is storing energy, not absorbing it. A shock absorber on a vehicle, for example, actually absorbs energy by converting it to heat. A ski binding doesn’t do that (other than with a small amount of friction).

In terms of results, insofar as I can tell in my lay reading of the standards, if the binding releases during the impact it’s a fail.

13. Now comes the field testing. Skiing on different types of snow is specified, along with more than 5,000 vertical meters. The standard specifies four testers who evaluate “unwanted release,” boot-ski connection, step-in, and exiting the binding. One has to wonder who those four skiers are, as they grade each binding on a 6-point scale ranging from “very good” to “rejected.”

14. Lastly, four of the poor abused test bindings get a dirty salt water dip and a salt misting. A 35% mean deviation is allowed after that.

Things ISO 13992 doesn’t cover:

– Location of binding/boot pivot point during lateral release, and how that influences results of standardized testing. Beyond the scope of the standard, an open question in binding safety is whether it’s safer for a binding to release to the side at the heel or at the toe, or both.

– Elastic travel of the boot within the binding (to absorb shock or store energy), is a huge factor in modern binding design. Both standards do little to test for this. The “recentering” test requires absorption (or storage of 45 Newtons), or about 10 pounds of force (if my math is right). The lateral impact test, when I saw it in person, did not appear real-world either. In my view, the best bindings should have quite a bit of elastic travel associated with enough energy absorption to prevent injury, while keeping you in the binding unless you really need a safety release.

– Regarding field testing, the specification says evaluate for “unwanted release” but says nothing about how on-snow testing should be structured to specifically evaluate this (huck a 30 footer?). Since pre-release is one of the most dangerous things to occur in skiing (head injury, anyone?), I’d think the standards would be much more diligent in regards to this. To be fair, the recentering test and impact test do address issues that influence unwanted release, but as stated above those tests could be more rigorous, and additional tests should be devised — both on snow and off.

– Safety release in touring mode is totally ignored. I’m not sure how this could be dealt with since most tech bindings have to be locked for touring mode. BUT, there are two mitigating factors:

1. Bindings can be built with a “soft lock” that increases retention in touring mode but doesn’t lock it out entirely. Apparently G3 Onyx and ION do this to one degree or another, as well as Fritschi Vipec. This easy to test in real-world use.

2. If the tech binding toe wing springs are strong, sometimes you can simply never use the touring lock. Lighter skiers with good technique can have success with this. This is a good thing to test with any binding, as sometimes you might want to tiptoe through a dangerous avalanche situation and optimize everything for safety, e.g., pole straps off, bindings unlocked, and so on.

In the same vein, retention in touring mode would be easy to test and is super important (as anyone who has walked out of her bindings in a kickturn knows). Not testing for this seems ridiculous, frankly.

– It’s no secret that many tech bindings have had durability problems related to the boot heel slamming down in touring mode, breaking heel lifters and other parts. Doing standardized testing for this would be easy. Put a 400 pound weight on the test sole in touring mode, drop the heel of the boot down, watch what happens.

– To the best of my knowledge, a major flaw in this ISO system is that pre-production bindings are used as test subjects. That’s why it’s possible for defects to sneak into retail products, defects you have a hard time believing did not get sussed out by TUV when they tested bindings for certification.

– Another issue here is “contributory effects” in real life use. For example, say your binding was getting axial loading, along with roll loading, as well as forward lean loading, it was packed with snow under your foot, and got shock loaded. As far as I can tell, even if a binding passed all the ISO tests, combining those factors could still give you a binding that worked poorly in real life — if at all. Perhaps that’s why we’ve been graced over the years by so many “certified” ski bindings that turned out to be junk.

Point here (beyond detailing the ISO binding standards) is that the alpine and touring binding standards are quite similar and at the same time meager. Yet they do function as a baseline guide for consumers, as well as a standard for insurance companies. Faustian bargain.

If anyone can help with accuracy, please leave comments. Oh, and please remember I’m not an engineer, so you pocket protector equipped geniuses out there, please be nice. With your help I’ll work hard to fix anything I messed up.

Check out this post about tech binding release adjustments.

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.