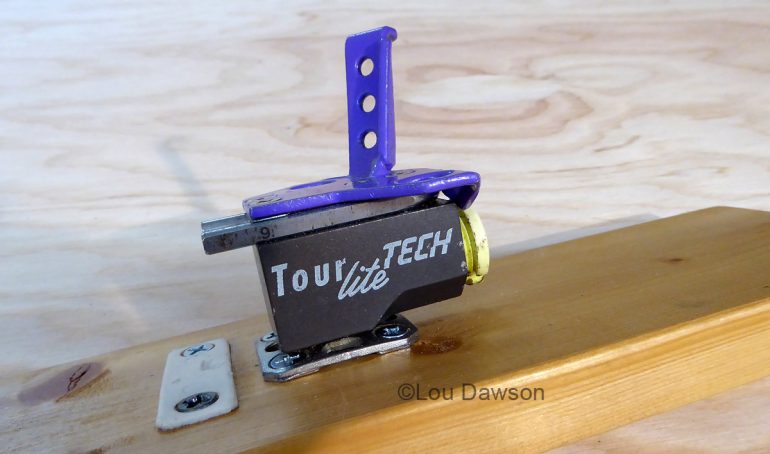

Winter of 1990-1991. Fritz Barthel had been developing his revolutionary “tech” ski touring binding for about six years. Around 1986, he’d begun manufacturing and retailing the binding himself — no ski company would license his patent (a source of much laughter ever since). He got to know the Dyanfit company when he bought thousands of their lightweight ski touring boots and installed the binding’s necessary boot toe and heel fittings himself. Dynafit took interest, licensed his patent, and the binding has been branded “Dynafit” ever since. This is essentially the same binding Fritz retailed himself prior to 1990, color purple being the blatant difference.

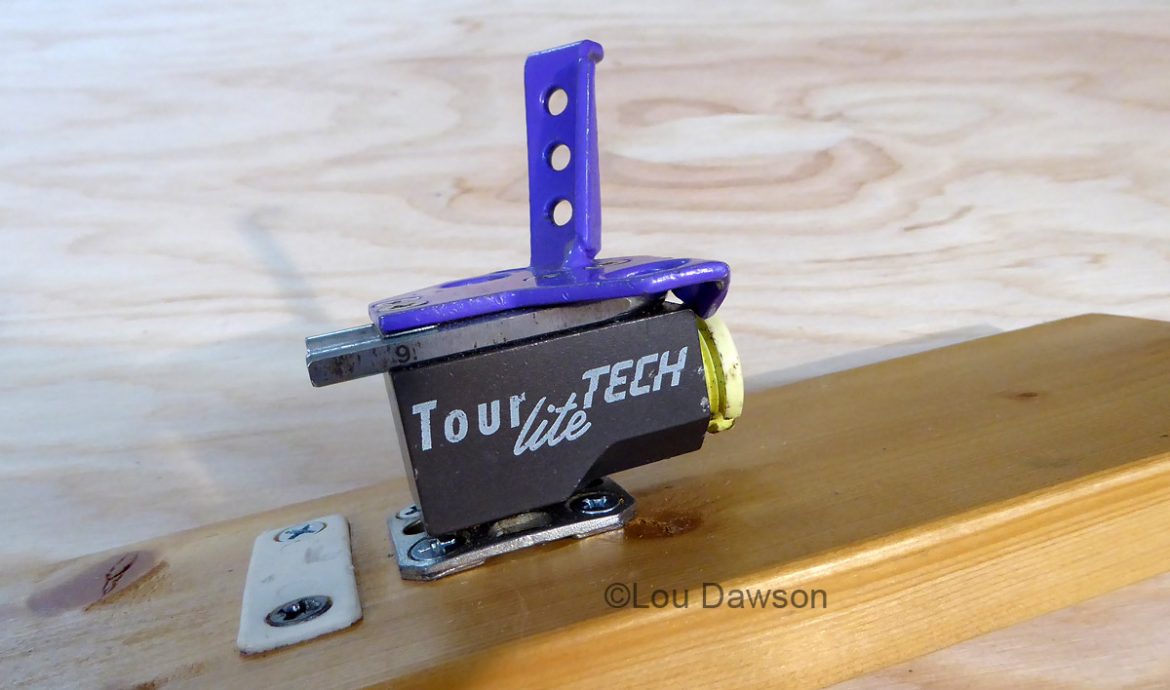

Branding, left side. The “official” name and spelling of this first Dynafit model has always been slightly confusing. Referencing this binding, as well as some of the printed material, I’ll term it the “Tour Lite Tech” and “TLT” for short.

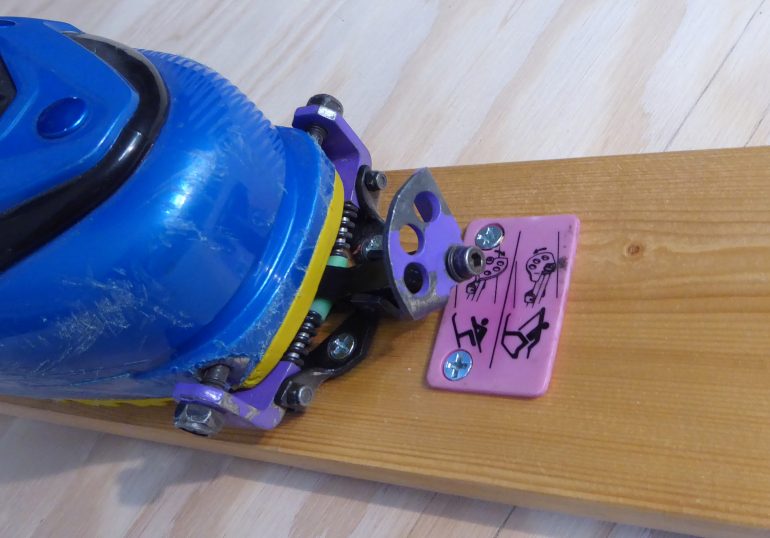

To lock the binding for touring, you rotated the crescent shaped wedge so it jammed against the plastic plate.

The entire toe unit, morphing to full industrialization, still had a pleasant homegrown demeanor. And you couldn’t argue with the festive coloration.

Heel unit not much different than previous generation, other than the branding. Note the binding this years still had zero adjustment for boot length. With at most a millimeter of tolerance, you mounted it it at yours or the ski shop technician’s peril. Boot length adjustment would come the next winter. The sighs of relief could be heard from Austria to France.

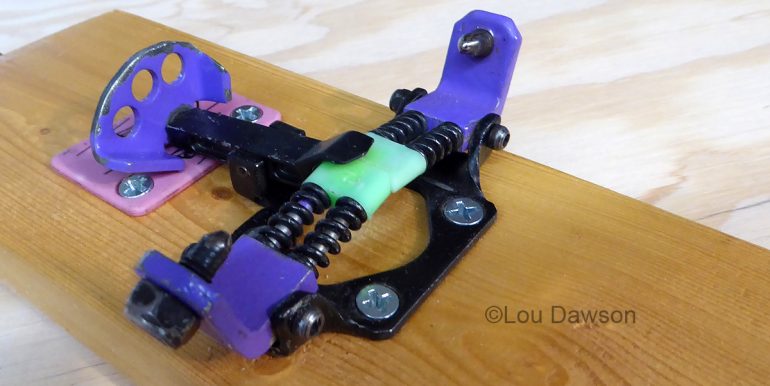

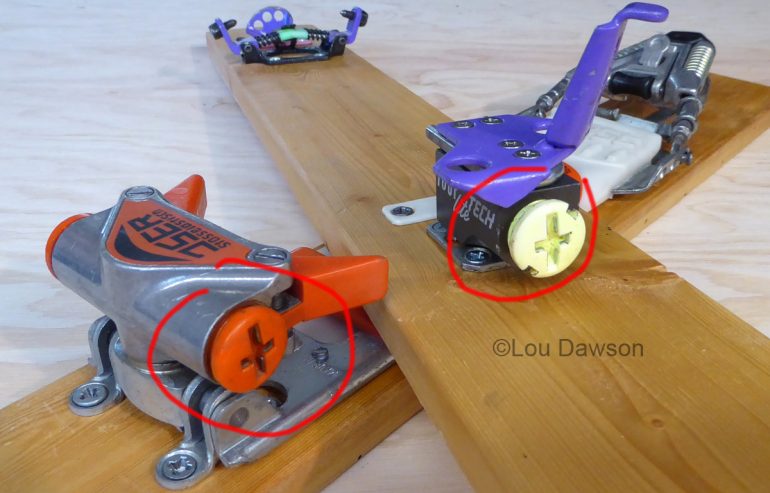

Fun historical trivia. When Fritz was developing the binding he needed a spring cap, spring and internal cam system to effect rotational release. Another touring binding of the time, the Iser, had a workable system. Fritz was able to iterate off that, and even obtained the spring caps (as pictured) from Iser. I guess they didn’t know he would virtually put them out of business.

I know a handful of inventors and industrial designers (including Fritz Barthel). They’ve educated me on how the world of innovation and invention progresses through iteration, and rarely involves an entirely new concept. The tech binding is a case in point. As not only did Fritz innovate on the Iser, but the ball-and-socket mechanics of the Ramer binding were his inspiration for the miniatured ball-and-socket of the tech binding toe. Fritz’s en-lightening inspiration was to eliminate the “frame” or “plate” most touring bindings used to connect toe and heel. This not only nixed the weight of the plate, but also eliminated the energy sucking action of lifting the binding heel unit up with each step.

As it turned out, the amount of weight the Tech binding saved took ski touring from a somewhat masochistic activity (try attaching seven or more pounds to each foot, not including ski boots, and walking around) to a sport nearly everyone can enjoy without needing hourly aspirin.

[To leave comments about this binding, please do so on our summary blog post.]