The new lineup adds flax, cuts weight, and ski really, really well

With a start-to-finish factory in Salt Lake City and Wasatch testing ground a mere 33 minutes apart sans traffic, it’s no surprise that DPS is able to pump out meaningful updates to their skis on short timelines. The master ski tinkerers have unveiled the new 2024/2025 Carbon Pagoda Touring lineup, which will be landing in a store near you, like Cripple Creek Backcountry, sometime this fall.

The big news about DPS’s new Carbon Pagoda Tour CFL family is flax. Yes, the fiber from the seeds in your granola that humans have been using for thousands of years. The new flax fibers are woven directly into the carbon fiber sheets that sandwich the wood cores to further dampen vibrations. Other updates include bio-based epoxy resin and 60% algal sidewalls from DPS’s neighbor, Checkerspot, throughout the line.

Wildsnow testers have raved about DPS touring skis for years. Slator Alpin toured their previous factory and detailed their ski building process back in 2020. Today, they’re handmade in DPS’s own factory in the heart of Salt Lake City’s Granary District, employing approximately 50 full time staff.

As part of their launch, DPS invited esteemed outdoor writers and media outlets to a three day launch, ski test, and factory tour in their Salt Lake City home at the beginning of April. I was able to weasel my way in, too.

Over the course of three days, DPS’s marketing team shepherded the small media crew through the factory, a mogul-bashing, steeps-ripping, piste-carving test day at Alta, and a guided backcountry tour in the Wasatch’s Little Cottonwood Canyon.

Touring in little Cottonwood Canyon

DPS

But first, like any good launch, it started with a crisp powerpoint in the heart of DPS’s hyper-modern shared office space. Built from and integrating the historic remnants of a locomotive factory, it was brimming with tech startups, sparkling shared kitchens, ping pong tables, and espresso machines buzzing away. It was hard to imagine that the ski company could be anything but the oddball in this building. But less polished than the crisp, techy offices surrounding it, DPS’s main office was more what you’d expect: Historic skis lining the walls, ski posters everywhere, and ski people bustling about working on ski things passing in and out of the adjoining factory.

Resins are critical to holding it all together. DPS uses bio-based resins from Texas.

There’s more to DPS than just fancy lightweight backcountry skis. Since their founding in 2002, They’ve pioneered the Phantom Wax system, partnered on a line of ATK bindings with a few special tweaks for the North American market, and they also make skis for the US Military including the 10th Mountain Division. After eight years producing skis in Asia, they brought production stateside in 2013. Since then, they’ve outgrown two other factories in SLC. But despite the high tech ingredients and engineering, their general ethos remains straightforward: “Build the best skis we can, and hope people like them,” described DPS’ Senior VP of Operations, Thomas Laakso.

DPS SVP Thomas Laakso sending it on tech bindings

Inside the Carbon Pagodas

As we rode up the first chairlift after the factory tour, I peppered Thomas and DPS’s Global Marketing Manager, Zach Clayton, with questions about carbon, flax, fiberglass, and other ski ingredients. Thomas mentioned that carbon, unlike fiberglass, has an unlimited fatigue life – they won’t break down in the core of the ski from repeated flexing like fiberglass does. Given their push to build skis with long lives, it’s a no-brainer. The catch is that carbon is six times more expensive than fiberglass on a gram-per-dollar basis. They’re also sourcing it from an aerospace manufacturer in SLC.

Thomas is a materials engineer by training, but now “plays an engineer on TV” as he put it, working instead on what seems like a big role in ski development at DPS. The man is obsessed with materials – wood, carbon, flax, epoxy – all of it. And it’s an obsession he shares with others on the team. No bases are good enough, for example, other than World Cup quality P-Tex 4000 race bases from Austria.

There’s an elephant in the factory and the DPS team addressed it head-on: DPS skis are expensive. A lot more expensive than other skis, even their high-end competitors pumping out of factories in Europe and Asia. Their 23/24 Carbon Pagoda Tour skis retail at nearly $1,700.

DPS does not stand for “Double Priced Skis,” Thomas joked.

Sheets of carbon sandwich the cores in the DPS factory. Carbon is expensive.

Jokes aside, DPS takes their craft seriously. Based on what I saw, heard, and felt for myself, they aren’t willing to skimp on materials, sourcing, durability, or performance characteristics to hit price points. On top of that, they’re keen on sourcing materials domestically when their standards can be met. Edges, for example, are manufactured in the midwest. Resins come from Texas. And like basically everything else, raw materials are getting more expensive. Those Texan resins, for example, have increased in price by nearly 80% in the past few years. Paying a living wage to workers in Salt Lake City isn’t getting cheaper either. It makes sense, then, that DPS skis aren’t getting cheaper.

Skiing the Pagoda Family

As we pushed off into the first run of the day, it was easy to feel the relative dampness and very even flex fore and aft while arching big turns on Alta’s groomed front side. I felt comfortable on the green 90mm waisted Carbon Pagodas after just a few turns; They were intuitive right off the bat and I felt nearly up to full speed behind Thomas, who was ripping deep turns on an experimental frontside ski they’ve been tinkering with.

After a few runs, I bumped up to the Pink 100 underfoot skis in the same length. Though their cores are identical, their shapes are quite different. The 100’s feature a tapered tip and tighter sidecut, resulting in a 15m turn radius compared to the 90’s 18m turn radius.

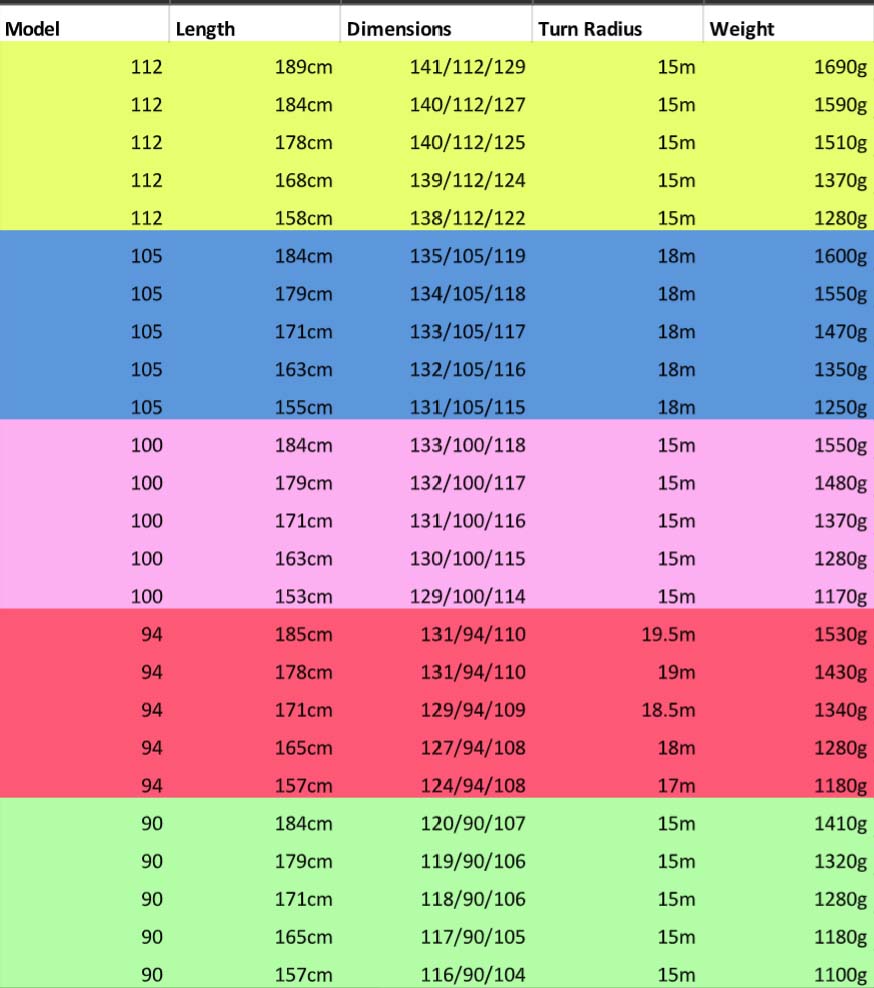

The skis in the new Carbon Pagoda Tour family alternate turn radii as they go up in waist size rather than forming a linear progression of increasing or decreasing turn radius. So picking the right ski for your style takes a little more thought than just grabbing the underfoot width you’re after.

Zach and DPS’ Marketing Coordinator, Erin Spence, guided us to some of Alta’s steeper terrain, which was graced with exceptional soft chop conditions. Both ex-racers, they tore into it without much regard for traditional limitations of lightweight skis.

I felt comfortable pushing the 100’s right out of the gate, too. As the shape and sidecut would suggest, they were quite agile, yet didn’t feel nervous. I was able to push into my Scarpa Maestrale RS’s and power through the choppy conditions, pop around, and put the skis where I wanted them. Would I want something beefier, damper, and a little straighter for day in, day out resort skiing? You bet. The Carbon Pagoda’s are dedicated lightweight touring skis, but I wasn’t left wanting much more in those soft conditions. That big 130 flex boot felt well matched, neither over nor underpowered for the entire Pagoda lineup.

I took the dark blue 105’s, which are a new shape entirely for the Carbon Pagoda family, out for the last few runs of the day. They also featured the same core, but bounced back to the longer 18m turn radius, which felt more stable and skied longer, as expected. “A solid ski for soft conditions, but enough bite for steep firm snow. Kind of a lightweight crusher” is the note I hammered out on the chairlift.

I asked Zach why they didn’t use any titanal in the ski under the binding plate. They said the Pagoda’s didn’t need them – they were able to achieve the binding retention with a P-Tex 4000 insert (same material as the base) and the carbon/Paulownia combo provided the torsional stiffness they were after. Plus, no metal in the ski means they’re able to skip the additional material, its additional cost, weight, and carbon footprint.

I believe them. From what I could tell over two days of testing, the torsional stiffness in each of these skis felt plentiful. We continued bashing through soft moguls and steeps until the lifts shut down. I pushed each ski as hard as I could and had a lot of fun doing it. We skipped the Alta Bombs, for better or worse.

Touring

The next day our gaggle of writers, two guides from The Backcountry Pros, and DPS staff tossed the DPS branded ATK’s into tour mode and skinned up the other side of Little Cottonwood Canyon for a few backcountry laps. One of the guides was fittingly riding a 12-year-old pair of Wailers, complimenting the marketing team’s durability assertions as if they were planted.

I took the bright pink 100mm underfoot 184cm skis for the day. As expected from such a light pair of skis, they felt light on the skin track. The relatively traditional mount points made them a breeze on kick turns. The torsional stiffness gave them a confident edge on the frozen sun baked crust.

Like a few other companies, DPS has their own line of bindings made by ATK. But Wildsnow readers will be psyched to hear that DPS insisted on 0 degree ramp angles instead of ATK’s standard, so they machined a custom base plate. Oh, and black screws were a must.

Over the course of the day, we skied through the full range of backcountry conditions – deep, steep powder, heavy spring corn, wind affected snow, etc. Like my experience the day before, the 100’s suffered almost nowhere for such a light pair of skis. They felt exceptionally nimble, but weren’t timid when I opened up the turns.

DPS Global Marketing Manager, Zach Clayton, hucking a backcountry backie

I wasn’t able to tap in a lightweight boot, but I’m confident that the 100mm, 94mm, or 90mm waisted skis in the 179cm length would be a great match for my Scarpa F1 XT’s. That’s a pairing I’ll be testing later this spring, so I’ll get back to you on that one.

Conclusions

I haven’t had nearly enough time on any of these skis to put together a comprehensive review (that will hopefully change), but the notes I took over two days of testing point me toward a few early conclusions:

- The new Carbon Pagoda Tour CFL family ski exceptionally well for their scant weight.

- They’re really expensive and now I understand why.

- The people working at DPS are obsessed with the minutiae of ski craftsmanship. They’d rather do it themselves than outsource.

- Alta and the Wasatch backcountry are incredible testing grounds for a ski company needing immediate feedback in diverse terrain and conditions. All the companies based in SLC are clearly way ahead of me on this one.

- DPS stands for Durability, Performance, Sustainability, which is not the original acronym

- Utah’s beer laws are silly

- If I had to pick one pair of the skis from the lineup to be my only ski for an entire season in Colorado, it would be the 100mm underfoot version in the 184 length. They’re just so dang fun and nimble.

DPS’s 2024 Pagoda Tour Lineup looks like this:

Bergen Tjossem is a ski fanatic, conservation professional, and nature nerd based in Vail, Colorado. His life and career have centered around protecting the natural environment and public lands that raised him, but as Ed Abbey put it, “It is not enough to fight for the land; It is even more important to enjoy it.” So when he’s not working his day job, you’ll find Bergen ski touring before dawn, ice climbing in the dark, running trails until his legs fall off, skiing 13er’s with his friends, or making the world’s best pizza with his wife, Rachel. You can find him on Instagram.