From the outside looking in, WNDR’s new showroom, The Nest, is situated in downtown Salt Lake City. The BelleTour splitboard is shown on the left, and the BelleAire is on the right.

Buzzwords abound when considering the “green” economy. WNDR Alpine, based in Salt Lake City, incorporates bio-materials into their building process and, along the way, nudges the ski and snowboard industry to think differently. WildSnow takes a WNDR Alpine factory tour and has a first look at their newly released BelleTour splitboard.

This story, like most stories about ski and snowboard manufacturers, begins with raw resources and concludes with unblemished bases and oh-so-clean topsheets, no-dinged edges, and deep powder fantasies. In peeling back the layers of this timeworn and over-marketed fantasy, Salt Lake City based WNDR Alpine, started in 2019, has matured into a small yet industry-leading ski and snowboard manufacturer making modest yet measurable tremors in the ski and snowboard space.

WNDR Alpine is the commercial arm of Checkerspot, a Bay Area company focused on developing and marketing biobased materials. We know of WNDR’s Algal Core, a polyurethane and domestically sourced Aspen composite. We know of their Algal Cast sidewalls – which are bioplastic sidewalls. They also have developed bio-based polyurethane foam, and a fabric, yeah, also bio-based, that has caught the attention of Gore Industries; think Gore-Tex.

WNDR’s Alex Andrews, Snow Product and Marketing Manager, is all hustle and bustle as WNDR eyes their initial foray into the snowboard market.

The language of bottom-line business are things like scalability, profitability, and, maybe, not so much, sustainability. (That’s a word, sustainability, we’ll get back to in a bit.) As a business, WNDR has carved out a nice niche; they’ve got a devoted skier and emerging snowboarder base. WNDR became the first certified B Corp ski company last February. (B Corps need to meet certain social and environmental guidelines.)

WNDR released their first snowboards this season in the BelleAire and the Belle Tour. More on that too, as WildSnow will be reviewing the Nick Russel prototyped-tested-and-shredded BelleTour this winter.

As the face of bio-based material in the industry, the literal retail and manufacturing face of WNDR in Salt Lake is a whitewashed and sunlit showroom called The Nest (an owl is their symbol). There we met Alex Andrews for a factory tour. Andrews is an excellent mix of core snowboarder and make-it-happen entrepreneur – his colloquial is a combo of dude and lab rat, something fitting for a place like WNDR.

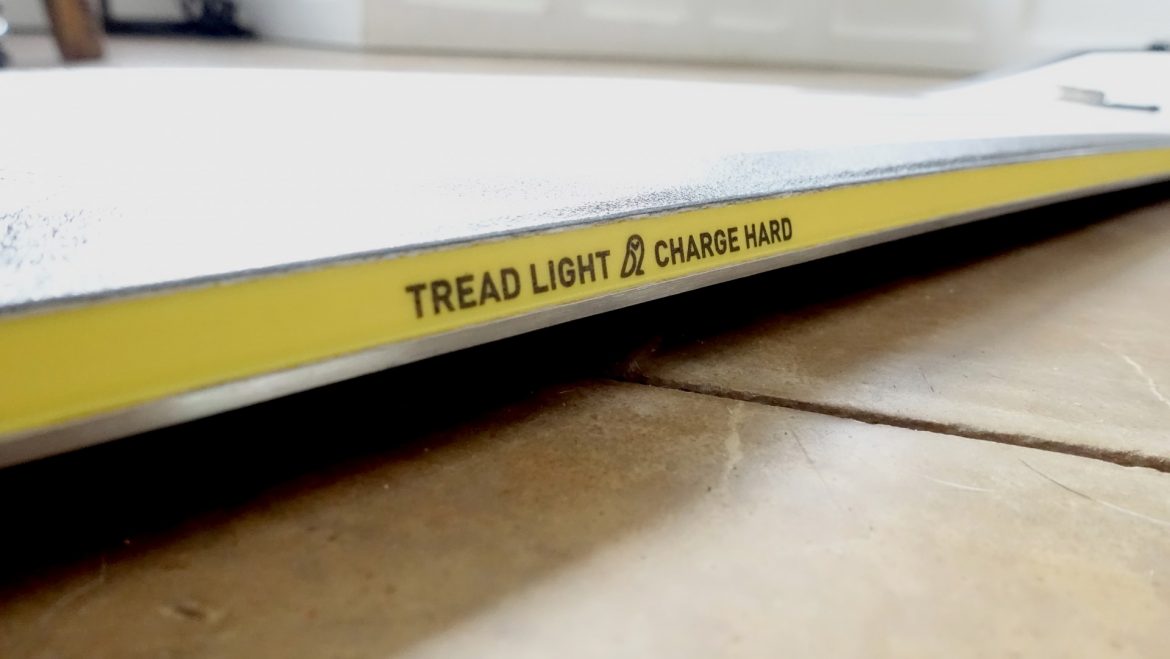

Here’s where we circle back to sustainability. That’s a loaded word often used in green-washing, yet, an aspirational word. And Andrews was careful not to use it. He understands the folly of claiming WNDR makes sustainable skis and boards. He also understands that while companies like WNDR push the industry towards more sustainable practices, the strict definition of sustainable, meeting current needs without adversely impacting needs in the future, is, as noted, aspirational. That aspiration, however, is more than lip service, cynical marketing, and clever branding logos on a ski/board’s sidewall at WNDR.

Here are several observations.

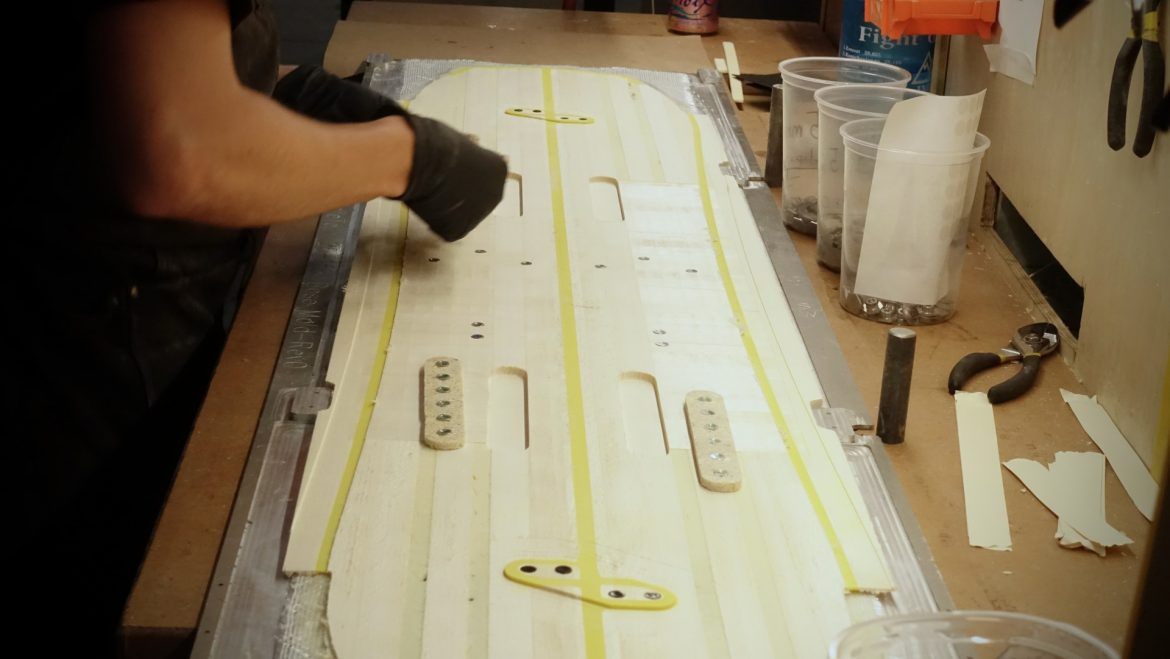

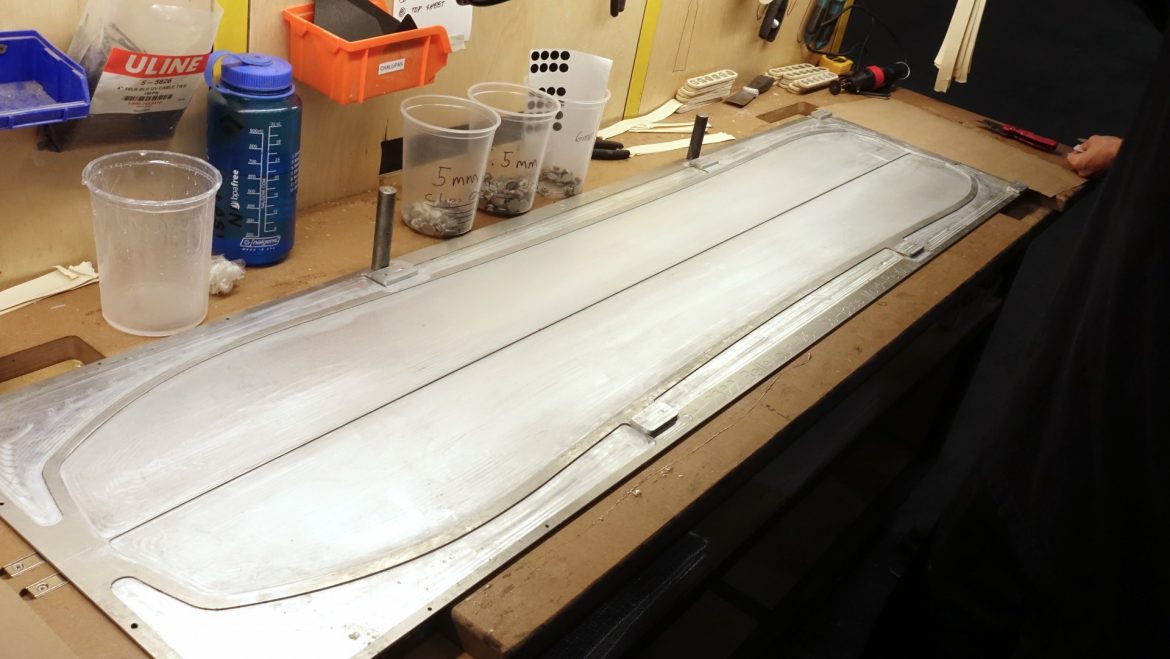

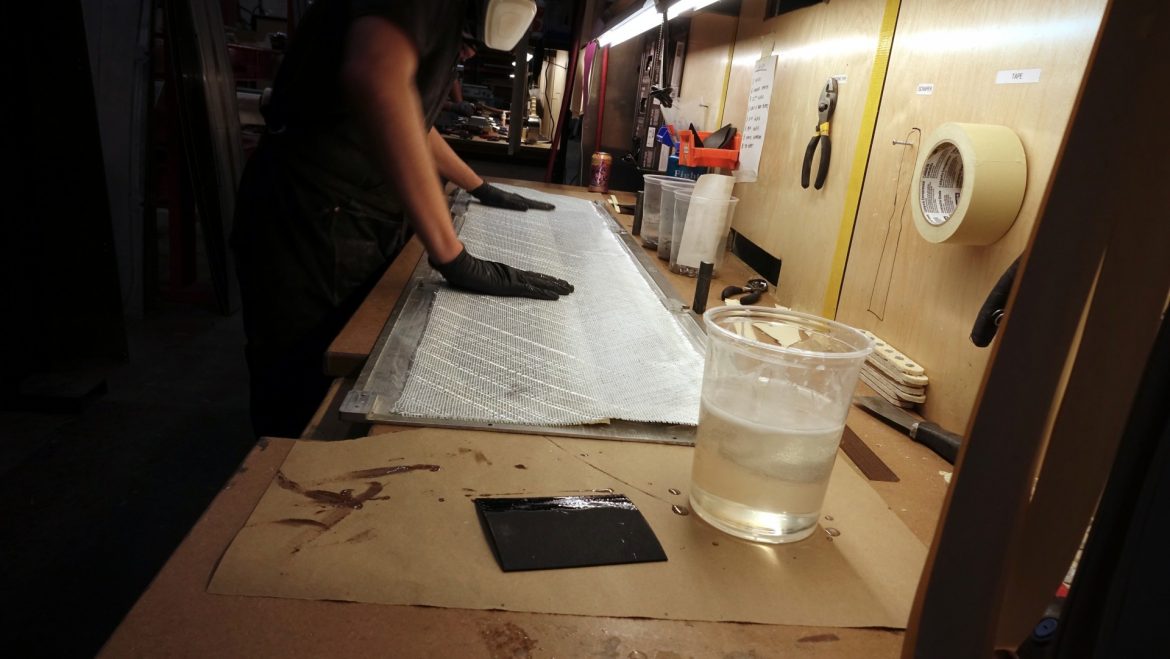

Each ski and board builder sees the product through from start to showroom. That means a single person is responsible for building, for example, the BelleTour splitboard I’m eyeing here in Bend. This means that the human capital at WNDR does not sit in front of a single workstation all day, repeating the same task repeatedly, like pouring sidewalls. The board builder literally builds the entire board. Maybe in some factories, efficiencies are associated with a builder staffing one station and becoming the expert in flattening bases, or adding edges, or epoxying the layup. But I also know the pitfalls of repetitive work: boredom, carelessness, and, sometimes, shoddy work. Not to mention the dehumanizing aspect of the literal and mental numbness all too common on the moving assembly line.

At WNDR, the factory, if we can call it that, was not a humming industrial cacophony: I saw maybe eight builders at different stages of the ski/board building process doing their thing. It all could have been a photoshoot marketing the release of a newly minted IPA from a boutique brewery. The hypothetical beer brand I’m imagining would likely overemphasize the word “craft,” “crafting,” or “crafted.” Why not try to capitalize on the coolness of the ski and board building process? Anyway, this is all just a thought experiment.

What I saw at WNDR was the real deal: This was not a staged photoshoot. It was folks building whole skis and boards to be used in places like the Wasatch. A place that would soon be the envy of the October/November skiing/riding crowd as the greatest snow on Earth would soon fall phat and plentiful in those hills.

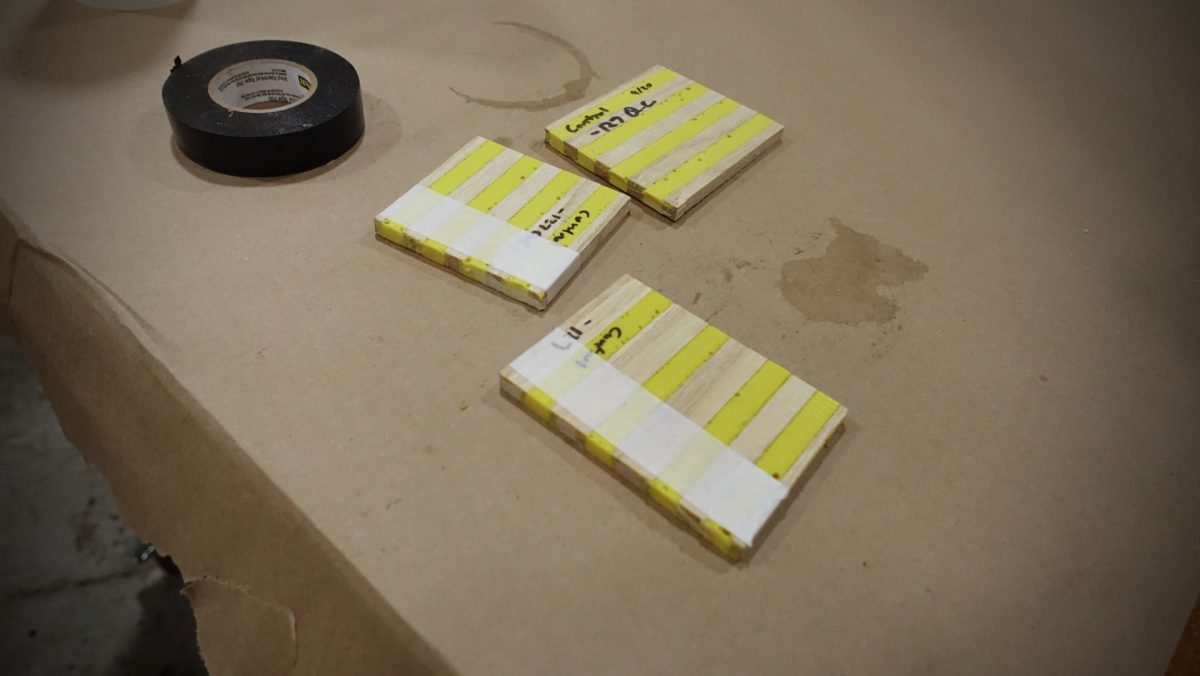

Then there’s the science. The science of it all was human scale too. This was no parody of a high school chemistry lab, but the word “chill” comes to mind when describing the four chemists I saw, all with white lab coats, who might as well have just come in from a lunchtime skateboard park session. They were, in fact, testing several new algal polymers and mixing up the respective batches.

WNDR walks a fine line. The facility is modern, with plenty of natural light, solar panels, and big-screened computers for modeling prototypes. It was also remarkably clean for any mid-scale production I’ve ever seen. (Andrews commented the facility was somewhat new and had time to break in and become cluttered.)

It’s clear that WNDR has the financial backing to sponsor an athlete like Russel and build a sufficient supply of skis and boards to meet demand. They are not a custom shop building each ski and/or board to a customer’s desired specs. The scale is hard to pin down; maybe somewhere between a mom-and-pop grocer and Whole Foods back when they had a handful of stores.

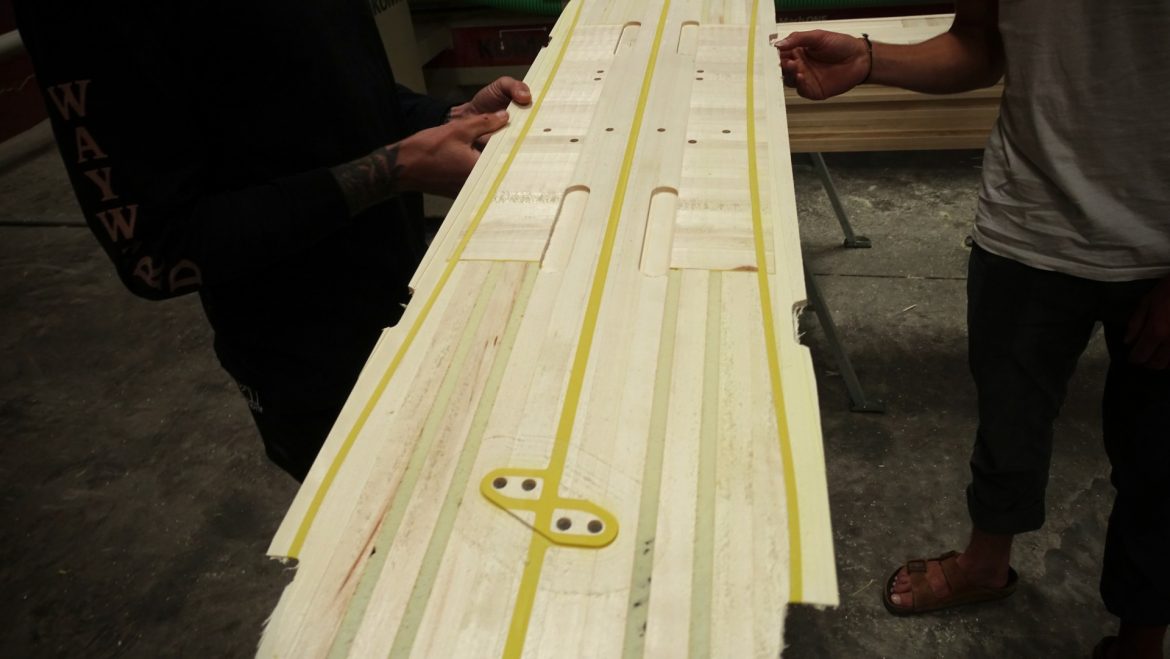

WNDR’s push into the marketplace in 2019 had legitimacy, as storied skier/shaper Matt Sterbenz, formerly of 4FRNT, helped found the company. So far, the products have withstood the scrutiny of the fickle ski scene. The company, too, has stuck with its underlying drive to reduce its reliance on petroleum products and waste. This year they introduced their SpiralMade program, which uses “flashings” (scraps from the ski and board building process) mixed with their bio-based resins to create retention plates in the binding zones of their skis and boards. SpiralMade plates replace metal or dense wood that would otherwise be sourced from off-site. The underlying vibe is the three Rs you had drilled through your brain starting in pre-school: reduce, reuse, recycle. WNDR says they have plans to use the SpiralMade materials in other regions of their snowboards next season.

Read WildSnow’s review of the WNDR Vital 100 and the Intention 110.

This is all to say that I was cruising through Salt Lake and wanted to get a better understanding of what’s under the WNDR hood. So I swung by. That’s a long intro to this brief first look at WNDR’s just released touring splitboard, the BelleTour.

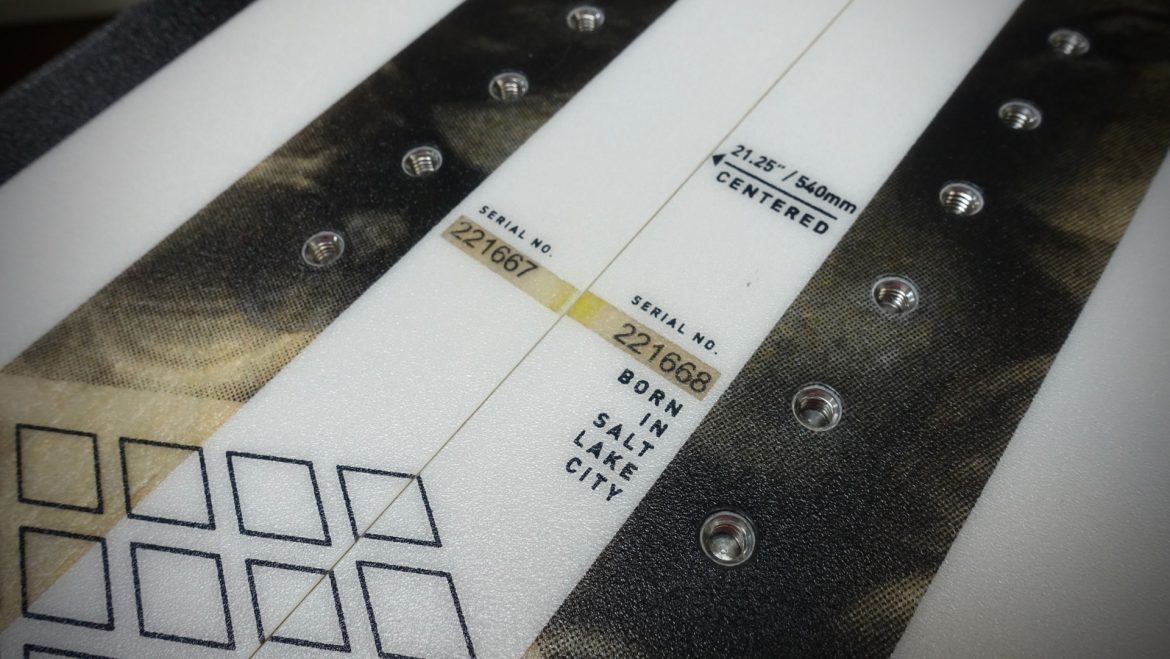

A simple topsheet for WNDR’s new BelleTour splitboard. The design and graphics are straight to the point and sleek, making it a visually appealing board.

Here are the BelleTour specs and a brief first look from Matt Colton, an under-the-radar split aficionado based in Bend. Matt is the bloodhound who always seems to locate the good snow.

BelleTour Specs

Length Tested: 159cm

Sizes Available (cm): 148, 152, 156, 159, 164

Claimed Weight: 3500g

Directional Camber: 5mm

Tip Width at Contact: 304mm

Tail Width at Contact: 294mm

Taper: 10mm

Waist: 260mm

Stance: 48mm

Stance Centered: 54mm

Stance Max:60

Price: $899.00

Matt Colton’s Thoughts

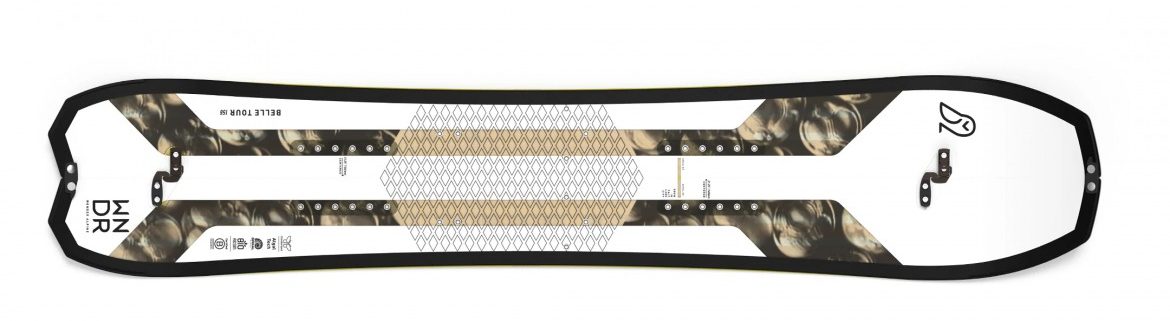

At first glance, the new WNDR BelleTour is a sharp-looking splitboard. Featuring an all-mountain shape, the board seems steady, solid, and powerful: definitely not the lightest board on the market for its size, but it looks like a good daily driver, and the construction is solid.

Given my touring style, I’ve never been much of a quiver board rider. I prefer one board that can handle everything. My touring style is multiday tours through wilderness areas, international trips to remote spots, and lots and lots of corn riding. I think this board will excel in all that.

But for someone who’s a good weather boarder and hits Japan for a month, chases storms around the West, and maybe won’t get out much during high pressure, this all-around shape may not compare with some of the more powder-orientated boards and shapes. I do know the intent of the BelleTour was all-arounder. So from my initial look, they seem to have checked that box.

The nose and tail clips are top-of-the-line, as well as the Karakoram clips. The width-to-length ratio seems spot on, and the construction and flex feel solid. The design and graphics are straight to the point and sleek, making it a visually appealing board.

I’ve been out a ton already here in the PNW, but you know how it goes; I’m waiting for the snow to in-fill a bit. Trashing a new board on sharp volcano scree would be an injustice. More to come this winter.

Jason Albert comes to WildSnow from Bend, Oregon. After growing up on the East Coast, he migrated from Montana to Colorado and settled in Oregon. Simple pleasures are quiet and long days touring. His gray hair might stem from his first Grand Traverse in 2000 when rented leather boots and 210cm skis were not the speed weapons he had hoped for. Jason survived the transition from free-heel kool-aid drinker to faster and lighter (think AT), and safer, are better.