Last summer I wrote about my little teardrop camper trailer project. Of course the project took longer than expected, and it’ll never be done. Recently I finished it enough to be usable (and enough that it warranted another blog post). Everything from this point on is just the final, mostly cosmetic touches.

A lot has happened since the last update. Last summer I had the foam structure finished, check out the first and second post for more details. Since then, I finished the exterior PMF coating, built basic interior furniture (bed and table), and installed a heater. I also made incremental improvements to various parts. I improved the drop floor by reinforcing it with another layer of plywood, and switching to steel cable for the windlass lowering/raising system (from the old nylon rope).

At the top of the list now is installing a ceiling vent, some wood trim inside, and storage under the kitchen counter. Farther in the future will be electricity, improved suspension/tires for off-roading, and a sweet exterior paint job (I’m open to suggestions).

Overall I’m happy with how the teardrop turned out. It’s nice and small, but just big enough. It’s light enough that towing only results in a drop of 1-2mpg; inconsequential for anything but driving to Tierra del Fuego and back. It’s almost unnoticeable while accelerating or braking — you have to be careful to drive like you’re towing (drifting corners is out), as you forget it’s there. I didn’t have the chance to use it much this ski season, but hopefully you’ll see it around the PNW parking lots next winter!

Here’s some pictures of the final product, as well as few from the build process.

View of the bottom of the trailer, showing the drop-floor (retracted). I used a rube-goldberg system with steel cable, pulleys, and a boat trailer winch to create the lifting mechanism. The weatherproofness of the bottom of the camper is a major concern. It’s got several layers of waterproof coatings: first a coat of thinned Polyurethane, then exterior paint, and finally spray-on truck undercoating. I’ve been keeping an eye on it, and it seems to be holding up.

The drop floor deployed. When the trailer’s on a flat surface, it simply rests on the ground. It can also hang from the cables if the ground isn’t level or flat (although then it feels a bit wobbly).

Inside of the front of the trailer, showing the drop floor, kitchen table, and heater. The area of the drop floor is all the “standing room” in the camper.

Drop floor retracted, from the inside. The camper is still fully functional with the floor up, so you can use it for quick stops, etc.

Rear part of the camper, with the table set up. It’s roomy for two people, and could fit up to 5 seated fairly comfortably.

To save space, and make the trailer shorter. The “default” bed is short (about 6 feet, so still usable). To make it longer, I added these slide-out extenders.

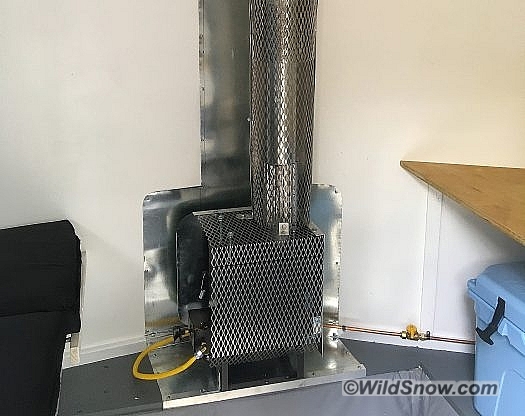

The heater for the camper. I opted for this propane ice fishing heater. It’s nice since it doesn’t require any electricity, and is super cheap. Downsides are that it’s bulky and took some work to install. I installed the expanded mesh screen to protect people from the hot stove, and it also provides a nice way to hang gear to dry. The mesh gets warm, but not hot to the touch, so no risk of melted boot liners or skin burns. I installed a CO detector of course, but the plan is to not run this heater at night while sleeping.

Before putting the “PMF” canvas on the outside, this is what the camper looked like. Pink foam, reinforced with wood and aluminium. The white patches are where screws, seams, and other imperfections were smoothed over with putty.

Let me know what you think!

Louie Dawson earned his Bachelor Degree in Industrial Design from Western Washington University in 2014. When he’s not skiing Mount Baker or somewhere equally as snowy, he’s thinking about new products to make ski mountaineering more fun and safe.