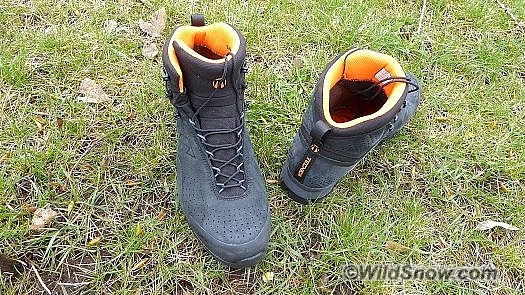

Tecnica Forge line of hiking boots includes CAS Custom Adaptive Shape system the molds both the upper and a custom bed.

When I was a wee lad of 23, I’d become frustrated with mountain boots that only lasted me a couple of NOLS mountaineering courses. I was working as an instructor, backpacking hundreds of miles on granite gravel and rocks, snow climbing, and even rock climbing in my big klunky leathers.

While I did practice exquisite denial about the cost of my gear, and was even then buying equipment on pro discount, I could not help but notice the cost of my boots was a good percentage of the money I made per course — coin which otherwise was destined to buy oatmeal for consumption in Yosemite. Giving up on mainstream products, I figured something custom built by Europeans in the Alps could perhaps last more than eight weeks. Specifically, the shoe makers in Kitzbuhel Austria, who I figured must possess the secret of cobbling boots that didn’t become tattered ribbons the first time they kissed Wind River granite. In a series of overseas letters and a scratchy international phone call, I ordered a pair of Haderer mountain boots, made from a tracing of my foot.

The Haderers were bomb proof. I’ve still got them for sentimental value, though the thick leather has become much too age stiffened for real-world use. Despite (or perhaps because of) their robust nature, the Haderers were never much for comfort (not to mention weighing a ton), they missed the key of in-person custom fitting, and you can only do so much with leather anyway. That’s where modern technology comes in. Whether it be ski boots are trail running shoes, touching the entire boot with a fitting process is the way to go.

This past winter, Tecnica introduced a technology in hiking boots to match the CAS Custom Adaptive Shape feature of their ski boots. While this being a fancy mouthful for the simple inclusion of lower density area of the boot that’s more easily heat punched (identified by a patch of small divots), the feature does work to make ski boots more readily heat punched, and is now featured with the Tecnica Forge collection of hiking boots.

Both Lisa and I had Tecnica Forge boots fitted last winter with the CAS system. The process involves molding a comfy footbed, then molding the actual trekking boot to your foot. The procedure was technical, clearly requiring a trained operator, but the results were excellent. I’m not sure every last trekker in the world would need this, but if you have the slightest tendency to foot issues or trouble fitting hiking boots, check it out. Below, the process in photos from a demo last winter. Lisa and I are using the boots and they’ve become go-to for both of us.

Next the boots are heated using custom shaped blankets, and prepared to be custom molded to your feet. )Unlike spot punching ski boots, the process actually works with the entire Forge hiking boot upper).

Both Lisa and I clearly got a molded boot out of the deal. In my case, left is obviously wider than the right for my more messed up foot, heel pockets feel like they were made for me. They probably won’t last as long as my Haderers, but they’re ten times more comfortable and weigh a third as much. Worth checking out.

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.