Andrew Nock

(Editor’s note: Andrew’s mod will get you thinking, and we hold hope that Salomon-Atomic will eventually provide their excellent divorced brake as an aftermarket kit that can be added to nearly any tech binding. See another approach to this modification. All photos here used by permission of Andrew Nock. This post sponsored by our publishing partner Cripple Creek Backcountry. They’re hoping Salomon Atomic comes up with a brake kit.)

I used 1 mm (3/64) carbon fiber plate (from Amazon) because it is easy to cut with tin snips, allows you to use your same heel screws, and seems as strong as (or stronger) than the plastic Salomon originally used (that I cut off).

Both a 1/16 and 1/8 spacer were experimented with. The 1/16 results in sad semi-droopy ski brakes. 1/8 has fully retracted, organized, ski brakes, but is difficult to press the boot heal down to lock onto heal pins as well as getting the heel out when you release the toe. It seems too tight. Each brand-model of binding, combined with boot, is going to be different in this regard and will require fine tuning.

Height of modified brake has is adjusted using thickness of base plate. (Note from Lou: One might think this could be accomplished by using the standard brake base, and adding spacers to the top of the brake retractor-actuator pad, unfortunately that’s not the case due to the brake having a part that folds on top of the pad.)

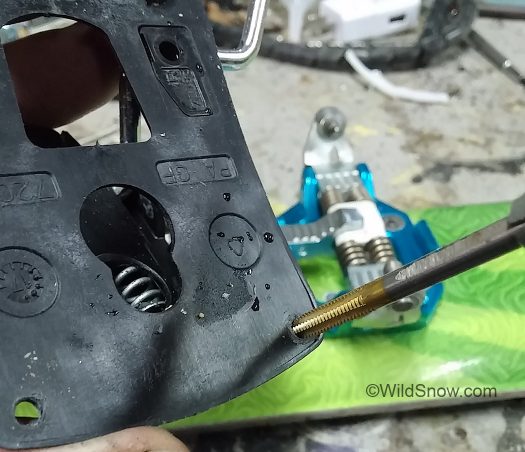

I tapped the front holes with 8/32 vs 6/32 to get better grip in the plastic. Seems to hold well when you tighten the screws.

Question. If I used 8.32 nylon black screws they’d be invisible and lighter. Is that going to far?

I am using 6/32 on the rear holes with small pattern (1/4) nuts. Normal nuts are 5/16 but the ‘small pattern’ 1/4 nut fits better in the small space. Note there is not enough plastic in the brake to tap where I placed the rear screws. A nut is clearly needed.

Question: Can the rear screws be moved outwards to the side ‘ridges’ and tap into a hole drilled into the ridges? This would eliminate the metal nuts.

Part Two:

Next, 90mm pair of brakes. I am going to try moving the rear screws to use tapped 6/32 holes into the brake’s edge ridges. That will get rid of the tiny nuts that are frustrating to handle and could get loose and be lost in the field. And here is the last option: using only screws tapped into the brake’s plastic. No tiny nuts. I found I can add 2 per side – for more security. Hard to say which is better just yet. Yes the tapped side screws worked, and have no nuts, but you have to be careful and accurate to get the holes drilled centered in the ridges.

Beyond our regular guest bloggers who have their own profiles, some of our one-timers end up being categorized under this generic profile. Once they do a few posts, we build a category. In any case, we sure appreciate ALL the WildSnow guest bloggers!