I recently enjoyed visiting Atomic headquarters in Austria, lots to write about. For now, in my opinion one of the reasons Atomic usually has ski racers on World Cup podiums is they have a highly technical corporate culture. While doing things by “feel” can be valid, one area where I’d like to to see more documented measurement is in the area of boot flex. The industry throws numbers around (130!) like a coach throwing soccer balls at a grade school field practice. My understanding is quite a bit of that is simply done by employees buckling into the boots and essentially sticking a number on what they feel, most often related to other boots in the same brand rather than an industry-wide standard.

Result, ski boot flex numbering can be a joke. But not if it’s actually measured with standardized mechanicals hooked to a computerized load cell. Our hope is that this scientific measurement done by Atomic — and perhaps certain other boot makers (let us know, happy to publish more) — will eventually work towards an industry agreed standard of instrumentation and reporting. Or, perhaps a third-party will lash up this type of machine and begin publishing results? In the latter case, the ultimate BS detector!

From Atomic, lightly edited for clarity and brevity: This was custom made for us by a local robotics team, it flexes the boot fore/aft to specified degrees/angles and measures how much Nm force it takes to reach those angles. The range we set is very realistic and achieved during normal skiing. When we hook a boot up to it, it provides us with the data you see on the attached chart- maximum stiffness and flex curve. It allows us to see how all of our own boots and competitors stack up against each other. We use this data to find out how stiff our competitors actually are vs. what they claim, and also to align our own boots as consistently as possible. If we see that we are too stiff or too soft for a given flex rating, we can adjust the plastic mixture accordingly. As you know there is no DIN, ISO or any other industry standard for flexes, so this data is incredibly helpful for us to deliver what we think are the truest and more legitimate flexing boots on the market. We like to think that if a standard would be developed for flex, we would be at the top of the list. This is even more crucial in the touring world where lots of lofty flex numbers and promises of progressive flex are made, but appear to sometimes not delivered.

Another view of the rig. Items of note: Some sort of artificial foot is of course essential, in the video you can see they’ve labeled this one as 26.5, indicating they might have different ‘feet.’ Atomic opts to test with the liner installed. I can understand why that might be the case, but it would seem better to test all boots _without the liner_ as well as with it, and create two flex curves. Or, perhaps simply test all boots without liner, since aftermarket liners and customizations are so common. Note how the boot is firmly clamped down, to eliminate variables in binding flex, while the boot is still suspended between two points as with most tech bindings. If the boot is set solidly on AFDs, that would presumably stiffen the flex a bit as the soles of ski touring boots can bow flex quite a bit. This machine resembles others I’ve seen in the industry that were used for cyclic durability testing, perhaps Atomic uses it for that as well.

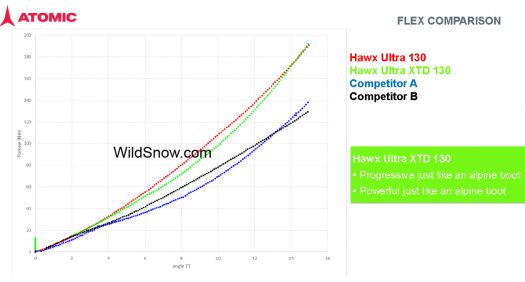

Machine results, forward flex comparison. Ideal for progressive flex is a curve that has a slight “belly” not a straight line. Though the straight line that climbs is clearly better than the horizontal line you would get in the case of a boot made from steel, with nearly zero flex. Click to enlarge, and you’ll see the Y axis is labeled with Nm (newton meters) which is a measurement of torque. Note in the case of Hawx 130 that the flex curve indeed intersects Nm 130. Thing is, that’s only at one point during the flexing of the boot, so the question arises, at what point do you grab a number to print on the boot? That’ll probably be another thing needing standardization. At the least, kudos to Atomic for relating the published boot flex number to actual measured newton meters, and high praise for actually using a nicely built machine to do so.

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.