Written by Jesse Morehouse

I have always loved well waxed planks for backcountry ski touring. I enjoy the task of waxing but I have no garage and find myself either paying shops or bumming off friends for space to wax. Or, in a pinch I’d do it out back on saw horses or the wood pile — acts of desperation that result in horrible wax jobs.

I dreamed of waxing inside but couldn’t stand the thought of the mess it would create. Then I went over to a friend’s house who is a waxing fanatic to get some pointers. He ushered me into the cleanest waxing setup I’d ever seen, compliments of a waxing box.

The concept is ridiculously simple which is probably why I for one have never thought of it. Make a box that you wax in and you get no mess. Duh!

Nice and clean!

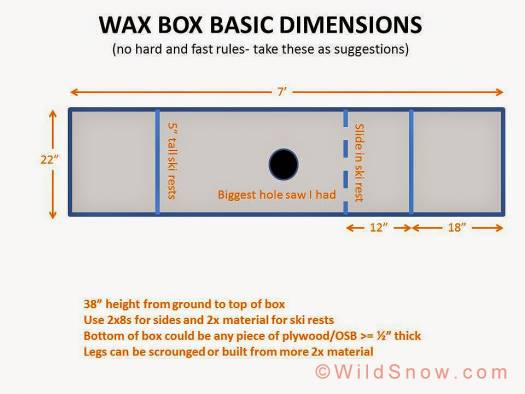

The basic concept is so simple I feel most folks could have me stop here and they would be fine. However, just for the sake of documentation and brainstorming, I’ll include basic dimensions (no hard and fast rules here) and some thoughts on tricking this bad boy out.

The Basics

Cut and sand everything first. Build a box out of 2x8s that is 7 feet long and 22 inches wide by gluing and screwing the sides together. It will be more efficient if you cut the ends and ski rests at the same time and make them all the same length.

One note on dimensions: the length should accommodate skis of any width up to 200cm long. The plans I made allow for a drop-in ski rest so kid length skis (sub 150cm) can be waxed. Check out the diagram and picture below for details.

Glue and screw a piece of plywood or OSB to the bottom.

Add the ski rests after ripping to 5 inches tall and if you want, with arched openings underneath to aid in wax cleanup. I also cut a 3/8 notch about 1.5-1.75 inches deep in the middle of each rest to hold skis on edge for wax cleanup of sidewalls and for edge maintenance. These rests are topped with pieces of a foam rubber from a snowboard rear foot pad. You know, for when those poor souls are hobbling through lift lines. The foam rubber keeps the skis from sliding around.

Scrounge some legs. Folding table legs would make it stowable if space is at a premium.

For cleaning out the wax scrapings, the hole in the middle has a small trash can mounted under it but you could just put one on the floor. A small hand brush like those cheap $2 “china brushes” in the paint section of your local hardware store does the trick nicely.

The ski rest and trash hole. You can see the notch for standing up skis on edge, the notches to slide in a shorter ski rest for kid skis and the arched hole under the fixed ski rest to sweep wax through. Key to this thing is a good polyurethane finish which allows the wax to be easily swept out. An initial thorough sanding followed by 3 coats with light sanding between worked for me. Pretty standard stuff and takes more time than all the rest put together. But worth it.

The waste bin. I bent some sheet metal into an ‘S’ that allowed solid mounting. A trash can on the ground would work too. The guy I got the idea from didn’t do any of this and just used a shop vac to clean out the wax. Many ways to skin this cat.

Customization Thoughts

There are a lot of things you can do to trick this basic box out. My friend had thin wooden pockets along the side for tools, a few hooks on the end, a magnetic holder for his metal scraper, one of those ski wax iron holders and a bottle opener. The bottle opener may be mandatory?

I felt somewhere to put the bottle or can once open was critical, wanted good lighting and a different tool organization plan so…

I added a top shelf basically just to mount a work light but subdivided it to stow waxing stuff. What you don’t see is one of these partitions on the end is fitted with a sheet metal liner so I can throw hot Ptex in it. Overkill but what the heck.

On the vertical posts I added some cheap screw-in hooks, bent a bit more open to hand all kinds of stuff. The red thing on the right post is a plastic scraper sharpener. The bottle opener is the dark plastic box on the far right- I got it from a restaurant supply house years ago with a build in cap holder. The scrounged legs have nonslip feet. The top shelf has beverage holders on the far right- a critical consideration IMHO. On the left you can kind of make out a power receptacle I mounted on the bench for the light and iron so I’d only have one cord running to the bench. Of course Id have to clean my attic to make that effort noticeable! A side benefit is I finally have a place to throw the stickers I’ve accumulated. Bonus!

One thing I’m thinking about is a sheet of thin plywood that drops in to fill the box, resting on the ski rests with some type of simple clips at the top and bottom so I can use this rig to perform skin glue maintenance.

It could, with some padding, be a great place for some dirtbag friend of yours to crash. Like I said, endless possibilities.

Anyway, those are some ideas. Im sure you can think of other very cool variations. I saw one on the Internet that was made of 1x4s and foldable for storage in a small condo type setting. Your imagination is your only limiting factor here!

(WildSnow.com guest blogger Jesse Morehouse is a middling but psyched skimo enthusiast who loves endurance-based outdoor adventures. He tries to keep the epics manageable on family outings, fearing his kids might revolt and become racketball players. He is always trying to save a buck with DIY projects so he can buy more skimo gear.)

Beyond our regular guest bloggers who have their own profiles, some of our one-timers end up being categorized under this generic profile. Once they do a few posts, we build a category. In any case, we sure appreciate ALL the WildSnow guest bloggers!