This just in: Fritschi sent along a few notes about Vipec compatibility with different boots. Apparently some confusion exists as well as the not unknown issue (with other brands and model tech bindings) of certain boot toe shapes hitting the binding and opening it. In our view, main thing with this binding is if you mount it yourself you’d better know what you are doing, or if not, find a ski shop that actually does have some expertise. Note from Fritschi follows:

Vipex Compatibility with alpine touring boots — information direct from Fritschi (lightly edited)

——– Alpine touring boots according DIN/ISO 9523

The Diamir Vipec 12 is compatible with all alpine touring boots that conform to DIN/ISO 9523 and are also equipped with “pintech” tech inserts.

——— Alpine touring boots with sole shape that is NOT DIN/ISO 9523 (e.g., Scarpa Alien)

• For alpine touring boots with the front “pintech” inserts behind the normal position like Scarpa Alien, Dynafit TLT 6, etc. we recommend installing the “Color Clip High” as an interim solution in order to assure a proper frontal release.

As consequence the toe of such boots hits the “Color Clip High” in a different angle in the position “walk”. In climbing mode it might happen that in an extreme position (knee close to the ski), the “Easy Switch Toe” is pressed down by the boot from “walk” to “ski” mode and may open the binding. For the next season we will offer a definitive solution with an adapted Color Clip for these boots.

• Light weight alpine touring boots with an extreme rocker are only compatible if the sole does not touch the front unit of the binding when the boot is stepped in.

• Light weight alpine touring boots without metal ‘pintech’ inserts like La Sportiva Stratos Evo, etc. are not compatible with Vipec. (Editor’s note: Someone really tried to use a boot in a tech binding without the boot having tech inserts? Sheesh….).

During the winter of 1995/1996, Fritschi L.T.D Swiss Bindings helped launch the modern era of ski touring with their Titanal frame binding. This was one of the first bindings to combine lighter weight and user friendly design — yet still give the the appearance of an alpine binding replete with toe wings and an over-center step-in heel latch.

Fast forward 20 years or so. Fameless “Tech” bindings have been around longer than that, but it’s taken those decades for skiers to learn that a backcountry binding doesn’t have to look like an alpine binding to ski like an alpine binding. More, eliminate the frame and eliminate lifting the heel unit with each step; you gain an extraordinary amount of efficiency — energy savings that increase exponentially the more steps you make (because the more tired you are, the more important each calorie saved).

Sometimes going to the source of the river is always best. In this case, our font of elixir being the Fritschi facility in Reichenbach, Switzerland. If location has anything to do with innovation, these guys have it, with the high alps of the Berner Oberland rising from the valley like a mystic monarchy ruling over its congregation of alpinists.

Out of the congregation comes innovation. In this case, the Vipec binding — resulting from Fritschi taking four years to develop their own iteration of what is now the tech binding virtual standard for a frameless boot/binding interface.

First, nomenclature.

I’ve been speaking with various Europeans about what they’ree calling the tech type bindings. Turns out the word “tech” doesn’t roll off the tongue for some denizens of the new world order known as the EU — thus the term “pin” is also used to describe tech bindings. Of course we in North America call telemark bindings “pin bindings” so using the term for tech binding doesn’t work. So how about “pintech?” We’re experimenting with the term, so we’ll use “tech” and “pintech” interchangeably. At Fritschi they like the term “pintech.”

How about the name Vipec? According to the Fritschi boys, they scoured the planet for names they could apply to the new binding. But “everything is taken, trademarked, so we had to come up with as unique a name as possible. We combined the words ‘Virus,’ ‘Peak,’ and ‘Scenic’ to come up with ‘Vipec.'”

Fair enough.

What sets Vipec apart from all other current tech bindings is side (lateral) release totally at the toe. As shown here, the toe wings fold down to effectuate release. Before that happens, a sliding carriage moves side-to-side to provide elasticity on par with alpine bindings. Make no mistake, most tech bindings have lateral release elasticity, but Vipec takes it farther. That's good, because with no release lockout, elasticity is the only thing that will keep you in a ski binding when using normal release settings.

Overall design philosophy of the Vipec project is fairly obvious to the experienced eye. First, hearkening to all of Fritschi’s other ski bindings, they kept the side (lateral) safety release at the toe. I’m not convinced this makes the binding any safer than a conventional “pintech” configuration with release mostly at the heel, but it does have the important effect of making the binding feel rock solid when you apply power under the rear of your boot during a turn. More importantly for safety, having lateral release only at the toe possibly minimizes pre-release tendency arising from powerful heel thrusts during aggressive skiing, and thus allows the binding to be set at normal release values — most certainly a safety feature.

Carriage holding front 'pintech' boot pin pivots slides left and right to provide release and elasticity, while the upright tabs also fold down for safety release.

During testing, for me the Vipec backcountry skiing binding felt quite similar to an alpine binding in that way and was noticeably different than the normal tech binding feeling I’m used to. More, I set both heel and toe to a reasonable RV 7 and skied some rough conditions including blue ice on a typical European ski touring “toboggan run” approach trail. No problems staying in.

Other safety features:

— The ski brake appears beefy and functional, and the binding can be configured to run with no brake.

— Available crampon is easily attached and removed via a pin-catch system, and has a cool flip-up spacer that optimizes use with higher heel lifts.

Installing crampon. You squeeze triggers with your fingers then snap the pins into place. Width of the crampon is not critical, so long as it fits over your ski. Thus, they don't have to make a lot of sizes.

— Perhaps the most important safety aspect of Vipec is that it does NOT have a release lockout. (Those of you who extreme ski on “pintech” bindings and like the lateral release lockout should note that while Vipec won’t lock, you can dial up the RV to 12 and essentially lock out release 100 percent unless you’re a giant.)

Vipec toe in walk mode. The small white plastic tab drops into a slot, thus blocking play in the toe; it is not a lock, the binding will still release.

This brings us to clarification of just what the front lever on the Vipec binding does, since it appears to be the same thing as other tech bindings — it is not. The lever has three positions. Pressed down with ski pole, it opens the toe jaws/wings for binding entry — as with most other tech bindings. Once you’re in, the lever automatically attains its downhill skiing position. Again, similar to other tech bindings; only in this case many skiers will be able to tour with the binding toe in the downhill skiing position, thus having the holy grail of safety release in touring mode (for example, if you’re caught in an avalanche while climbing.)

When the binding is open for entry or in downhill mode, the slots are open as well, thus allowing elasticity of the carriage holding the toe wings.

What you’ll notice while touring with the toe in downhill mode is you get quite a bit of side play due to the binding’s elasticity and tolerances. While I did’nt find this to be a problem in testing, Fritschi told me that this movement can influence kick turns and compromise traversing. So they put in a third mode for the toe lever that blocks out most elasticity and side movement (as well as preventing bumping of the boot toe from easily releasing the binding. Safety release is the same (I tested) but you don’t get much play.

Color Clips for Vipec toe. Black one to right is designed to compensate for unusual boot toe shapes, yellow to left is cosmetic and can be left off.

Along with all the above, Vipec comes with two different plastic covers for the toe lever. One is standard and only cosmetic, while another is intended for boots with toes that can bump into the lever and release you out of the binding accidentally during kick turns. They call these add-on bits of plastic “color clips” since they’re available in different colors so you can personalize your bindings.

Compensation for boot tech fitting is done by rotating threaded "pintech" pin in binding. While Scarpa uses standard Dynafit fittings and thus usually will not require adjustment, other brands who make their own fittings may need this tweak. Getting it right requires testing the boot for play, release, and ease of entry and exit. Fritschi says that 80 percent of the boots out there will NOT need this tweak. The standard dimension is set at the factory.

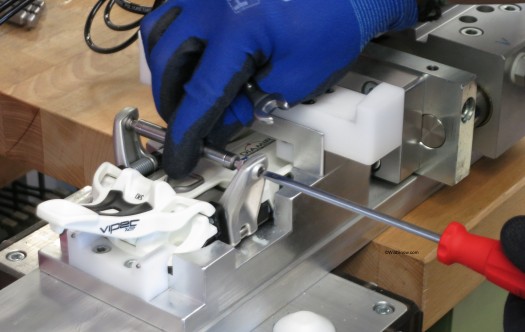

Next in line for important Vipec features is the boot toe tech fitting compensation. Of any part of the binding, this has the most potential for confusion — if not abuse. You’ll notice that one of the toe pins on the binding toe wings is threaded and adjustable, with a lock nut on the inside and screwdriver slot on the outside.

While mounting the binding, you must snug up the lock nut on the boot compensation adjustment gently. We like this feature, but it does have the potential to muck up the do-it-yourself binding mount. Know that this sort of thing would be unnecessary if the industry would get their act together and make a standard for 'pintech' boot fittings. Word I hear is don't look for this to happen anytime soon--too much politics.

The idea here is that most (Fritschi says 80%) brands and models of boots have accurately standardized toe fittings, yet some do not. For the 80% the Fritschi factory settings will work, but the adjustable fitting can be moved up to 1.2 mm to compensate for non standard boot fittings. Important factoid here is that the lock nut on the adjustable pin should be snugged up during the binding mount process after the boot is function tested and verifies that everything is working correctly. If the boot tends to rattle in the fittings, or the binding doesn’t open or close correctly, then adjustment may be required.

Ok, next on the agenda: “Forward Pressure,” the tech binding feature of 2014 that rivals carbon fiber in esoteric desire. A solution or a non-issue depending on who you are and how you ski, “forward pressure” systems appear to be here to stay. In the case of Vipec you adjust the heel unit with a very small gap between boot heel and binding — there is no big gap as with many other “pintech” bindings. The binding includes an indicator that tells you when adjustment is done correctly (slight movement of a black plastic part “flags” your adjustment) — overall the adjustment is easy. Mainly, avoid the temptation to screw more forward pressure into the system under the mistaken impression that this will somehow make the binding perform better — or in the case of being incredibly tech ignorant, somehow actually improve your skiing.

Another Vipec feature is you can honestly switch between downhill and uphill modes without removing your foot from the binding. This can indeed be nice, and tested well for us during a ski tour here in Schweiz. It’s a simple matter of moving a lever up and down. Speaking of which, all the ski pole actuated levers on the Vipec heel expect a fairly rigid pole basket or pole grip with a small “hooked” configuration. My pole with a soft plastic powder basket and straight grip did not work all that well, though I was able to get things done when necessary by simply trying a little harder — or reaching down with my hand.

I’d give Vipec medium marks for ease of use. While flipping the heel lifers is intuitive and changing modes is also easy, getting your boot toe to latch in can be hard due to how the Vipec closure trigger works and the absence of any sort of boot positioning feedback. In other words, in this respect we’re back to early tech bindings that require the user to click-in with care. Definitely not “step in.” Saving grace is that you could conceivably click into Vipec once in the morning and leave them on all day since mode changes are so easy. Another thing I should mention regarding easy use is all normal adjustments can be done with a pozi #3 screwdriver bit, thus helping simplify the rather extensive tool kits some of us Boy Scout types have been carrying.

My conclusions after extensive technical orientation re Vipec, as well as skiing it? First, in a humorous vein it’ll be interesting to watch how quickly the country of Switzerland changes over to using a pintech binding now that their national brand provides one. Prior, it’s been amusing to see how nearly all bindings in countries such as Italy and Austria are tech, then you’ll do a tour in Switzerland and you might not even see a pintech binding — everyone will be using Fritschi frame bindings.

Serously, my impressons with Vipec are it 1.) Provides a very alpine-like feel due to the solid heel unit and 2.) May be quite safe for leg protection due to the side release at to having significant elasticity. Beyond those things, biggest differences from most other “pintech” bindings: Easy change modes without removing skis, and no release lockout uphill or down.

Four years, 27 technical prototypes, 52 molds. It all shows in what appears to be a highly engineered machine. Again, garage binding builders move over. Another big kid is in town. His name is Vipec.

Kit for running with no brakes. Black plastic screws on where brake usually mounts. Note that changing brake arm widths only involves swapping the actual arms, not the total ski brake. Hopefully that'll make running different widths of brakes cost less and be easier for consumers.

Please see our previous Vipec articles.

Shop for Vipec backcountry skiing binding.

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.