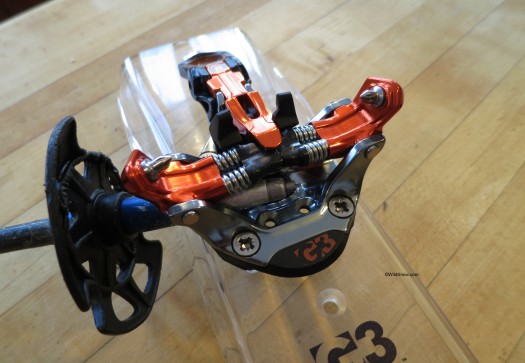

G3 ION tech ski binding, based on the standard tech binding but with enough added features to easily set it apart. Click images to enlarge.

Look out garage entrepreneurs — G3 is in town and they have a really big garage. Indeed, the days of essentially copying tech bindings and selling them out of your workshop are probably over for good. Today’s proof: Witness G3 ION — a backcountry skiing tech binding with a long list of supremely innovative features that you’d be hard pressed to develop without extensive materials and mechanical engineering skills.

Note: It’s becoming common among some Europeans to call tech bindings “pintech.” We had a lot to do here at WildSnow with the word “tech” coming into use to name these types of ski bindings. If the trend is to use the word “pintech” we’ll support that as well. Thus, we’ll use the word “pintech” occasionally to see how it lifts off the tongue.”

Our bloggers have skied the ION; I’ve given it a once-over clinical exam that even included digital methodology. Results are in two blog posts: Below, as well as Louie’s on-snow ION abuse.

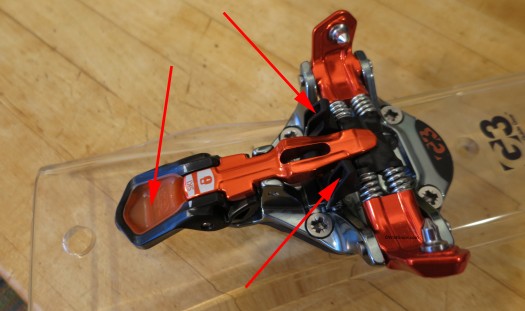

Looking down at ION toe unit from user perspective, the Toe Stops (indicated by red arrows) are the most obvious difference. They rise up when binding is set to receive boot, then move down when the boot is inserted. Quite nice, though they only work for standard DIN boot soles, not for trimed toe boots such as skimo race shoes and lightweight touring optimized boots.

ION PR claims and more, with comments by Lou:

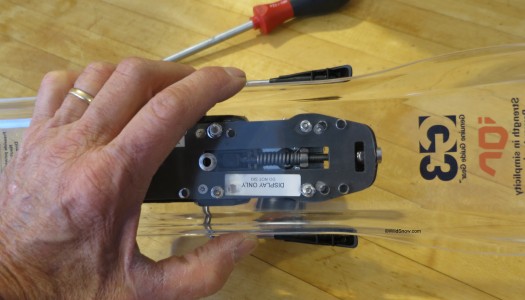

Partial ION heel teardown reveals typical 'pintech' binding construction. Improvements over the standard and ION's unique features are subtle.

“Lightweight.” ION catalog weight of 585 g, 20.6 ounces per binding (1/2 pair) with 115 mm brake and no screws is claimed. That’s not particularly light for a “pintech” binding (competitor major brand with similar features weighs slightly less though exact models and brake widths cause apples/apples comparison to be tedious), but if the heavier duty toe wing springs and heel fore/aft elasticity help with reliable retention, the added weight could be worth it. As we advise time and time again, “if your tech bindings work for you, added features will not change your life, but if you have problems with current tech bindings these new features could be answered prayers.”

Our pre-production binding weighs the following with no screws:

ION toe: 6.1 ounces, 172 grams

ION heel with 105mm brake: 14.8 ounces, 420 grams

Total pre-production ION 20.9 ounces, 592 grams

“Class leader; no other binding with RV12 and brake is lighter.” True to the extent of comparing to complete stock bindings, but remove the pretty much cosmetic connector plate between toe and heel of Dynafit Radical FT and it weighs in at 552 grams (new model with heel spring elasticity), ST model is similar in weight and goes to RV 10.

“G3 ION jaw retention is industry’s best.” Could be, as G3 started their quest for this with the Onyx binding by using strong springs in the toe wing mechanism. We continue to try and measure this on the WildSnow bench, but field testing by aggressive skiers is probably the best way to evaluate. That being said, G3 does have the electronic equipment to test toe jaw retention in a controlled but dynamic fashion. I’ve seen the charts with the graphing and I’ve also seen the test machinery in action. It’s not child’s play but rather the real deal. Their values are consistent and high. Of any feature in a tech binding, this could be the most important as it allows the binding to be skied unlocked, aggressively, with less chance of accidental release.

“Wide freeride mount.” ION is said to be “30% wider than traditional tech bindings, with 40 mm spacing of all the toe unit screws. We continue with the opinion that most people will notice no difference between this and a traditional tech binding screw hole pattern. Nonetheless, some of you do need more strength in this area and you prove it by pulling bindings out of skis. In that case, ION may deliver your desires. (Wider screw patterns and binding base plate widths probably come into play more realistically with skis over 110 mm wide at the waist, combined with stiff boots and larger more aggressive skiers. But wait and watch, just about the time most tech bindings get wider, I’ll bet the touring skis market will stabilize at more the sub 110 mm width due to weight concerns and such. Funny if that happens. Dog chasing tail and all that.)

“Neutral delta (ramp) angle matches freeride alpine bindings.” In any case, center of binding/boot pins from top of ski: toe 40 mm, heel 53 mm, difference of 13 mm which is virtually same as early Dynafit TLT and our favorite binding delta angle. (Also, virtually same as G3 Onyx). This is not what I’d call “neutral,” though it is said to match that of alpine/tour bindings such as Duke which are known to have less delta than some of the harshly tilted tech bindings on the market. See our ramp angles post and chart here.

Snow clearing channel is a function of the binding toe being raised up to reduce ramp angle. This in turn allows G3 to include lots of space under the toe wings where snow or ice can block proper function of the binding. All tech bindings require great care with this, as ice blokage may cause your binding to appear closed on your boot toe, when in reality you can ski out of the binding and take a nasty fall. Anything to help with clearing ice and snow from this area is a welcome improvement.

“Snow Clearing Channel” Is an excellent idea. G3 molded in a lateral (left/right) space under the binding wings that drops close to the ski top and is big enough for a ski pole tip. One of the biggest problems with tech bindings — and something that in my opinion has probably caused a few deaths — is that the binding wings will not close fully if ice gets jammed underneath. But, in such situations they may close just enough to give the illusion of full function, only after a few turns you can pop out of such an ice jammed binding and take a nasty fall if you’re in high consequence terrain. Addressing this issue at retail, without consumer modifications, shows that G3 is in the real-world with their product engineering.

Boot toe stops providing what G3 calls 'Step-in Guidance' are the black prongs sticking up in front of the boot sole. I'm impressed by this feature, though its effectiveness is reduced by ice or snow getting in the way, and it doesn't work unless your boot sole is the standard DIN shape at the toe. What's slick is that the prongs raise and lower as you exit and enter the binding. They're 'active.'

“Step-in Guidance.” This cool feature is probably not 100% effective, but attempts to address the buggabear of getting your boot toe in position to snap in the toe wings — a particularly heinous challenge for the newbie and what makes tech bindings demand superior athletic ability. Basically, the two black plastic towers rise up when the binding is open, help index your boot toe, then lower down when the binding closes. I know for a fact that other companies have been working on similar systems. Other than the major brand’s “Power Towers,” I know of none that made it into retail.

The toe stops again... an excellent feature. They appear to be easily removed by advanced users seeking to make the binding lighter.

“Stow BRAKE on first step or in your hand.” This deserves exposition. When you rotate the heel unit to touring position it engages a series of catches to hold the brake up,on ly the brake does not rise and stow automatically, instead you either step on it (in heel-flat-on-ski mode) or squeeze it closed with your hand. When done correctly you’ll hear a satisfying click and the brake is ready for touring. Worth mentioning again that the brake could be left deployed as a climbing aid or to save your skis from running away while you’re messing around clicking in. It’ll be interesting to see where that idea of brakes as climbing aid goes. Oh, also, G3 says their brakes are heavier duty with engineered tips to increase stopping performance. We’ll see if they’re really much different once consumer testing commences. To me this is a non-issue, but ski brake performance (or lack thereof) is indeed a constant thread in discussion of tech bindings — perhaps ION will be the standard setter?

Additional observations: The bi-directional heel unit and climbing lifters are impressive. Simple. When changing modes, you can rotate the heel unit either clockwise or counterclockwise — the flip-up heel lifters work either way. This results in a much more ergonomic and intuitive feel to the system. Just reach down and turn the heel unit, don’t bother remembering which direction. Anti rotation? Taken care of by the brake interlock. Ah, and lastly, can the brake be removed for weight savings? Not easy, but we think it’s possible.

Medium 'regular' climbing lift is a simple flip-down tab that works either direction depending on which position you rotate the heel unit to.

ION heel-flat-on-ski mode rests on brake and moves it a bit each step. Not sure that's ideal but time will tell. Perhaps production version will have some sort of solid heel support in this mode.

Once binding heel is rotated to touring mode, the brake lock (indicated by arrow) also takes care of blocking accidental rotation. In our view, nearly any tech binding can 'auto rotate' on ocasion, but ION appears to be nicely secure in this way. Consumer testing will render the final verdict.

“Forward pressure.” Energy absorption (ski flex compensation) in the heel of tech bindings is the latest craze. Is this a solution without a problem? For myself that’s most certainly the case. But the aggressive skier with big boots and skis could benefit from the binding heel unit sliding fore-aft a few millimeters under spring load to compensate for the ski flexing. Yet any new mechanical system introduces issues. For example, if the system moves with every step, will it wear out prematurely? Or is it durable enough from the start?

Consumer testing will answer those questions, but one thing we like about G3’s “energy absorption” solution with ION is that the fore-aft movement of the heel is locked out when you’re in touring mode. My guess is that high mileage individuals may find the lockout be a highly desirable feature to prevent wear. Just a guess, however. We’ll know the reality by springtime after some of these ‘heel spring’ bindings have several hundred thousand steps on them.

Important thing to know is that these “forward pressure” systems have NOTHING to do with release elasticity, their sole function is to compensate for ski flex and keep release values consistent. Thus, they may have little to no effect on accidental release behavior of the binding.

(Note that boots that flex at the ball of the foot are verboten for this system, due to the sag of the boot interacting in unacceptable ways with the heel unit movement.)

So called 'forward pressure' spring is visible underneath on the demo board. Six millimeter of travel. Our seat-of-pants engineering side has to ask how a tiny spring with only 6 mm of travel can really make any difference in how a binding skis. Getting it on snow for extended use will tell the tale -- though one has to suspect that this sort of thing is more for the purpose of getting the binding certified by TUV to the DIN touring binding standard, rather than any revolutionary real-life quantum improvement in tech binding technology.

Forward pressure system allows the binding to be mounted with no 'tech gap' behind heel. Most tech bindings compensate for ski flex by the heel pins sliding fore-aft in the boot heel fitting. This is an innovative and incredibly simple solution, but has the problem of unpredictable friction as well as limited range. We've always felt the system could be improved by adding longer pins with a slightly wider tech gap, but binding engineers seem to be going the other direction by closing up the tech gap and building the shock absorption and movement into a spring loaded heel unit.

A few points specific to the so called ‘forward pressure’ of ION binding. First, when the binding and ski are at rest, the heel unit is adjusted so it just touches the heel of the boot. In this situation there is NO forward pressure. When the ski flexes and the boot presses back against the spring loaded heel unit, then yes, something you could call ‘forward pressure’ exists. In other words, this is not the ‘forward pressure’ of the type you adjust a conventional alpine binding for — those usually have some pre-load. More, as mentioned above it bears repeating these sort of “pintech” binding ‘forward pressure’ systems do not provide release elasticity, meaning they’re not providing any sort of return-to-center help with vertical (upwards) release. Instead, they’re simply there to allow the ski to flex and possibly make release values more consistent depending on ski flex.

With ION and most other tech bindings, despite the heel springs the amount of vertical elasticity in the release system remains the same: minimal. Thus, we still wait for tech 2.0 — though don’t forget at least one tech type binding does exist that provides additional vertical heel release elasticity — and more may be coming.

Another view of toe unit. Left arrow points to a nice PU pocket for your ski pole tip. No more shattered plastic? Right arrow points to the boot toe locators. The front lever locks and unlocks the release as with most other tech bindings.

Underside of rear unit, with hand for scale. The screw pattern of the rear is about the same width as other tech bindings, but is designed to mount over other hole patterns without unacceptable overlap of screw holes -- a smart sales touch for the 'new kid on the block.' More, if a shop has demo skis mounted with the rental ION version, they can re-mount with the regular ION and the rental holes will be covered up. Perfect for selling out those rentals when the time comes.

More specifications:

•Release value (RV) range: 5-12

•Boot length adjustment range: 22 mm (similar to other major brand)

–(62mm for Demo/Rental Version)

•Brake sizes

–85, 95, 115 and 130mm

•Ski crampons

-85, 110, 130mm, can be mounted to any backcountry ski by using available hardware.

MSRP

– Street price will probably be around $500.00 once the initial buying panic is done. Actual MSRP is $549.00 USD

And get this: G3 even has as an accessory a set of M5 mount screws to use with insert kits, at the correct length and with thread locker already applied. How excellent is that?

In all, we are highly impressed by ION. This machinery appears “mature.” Unlike virtual copies of the original tech binding hailing from Fritz Barthel’s mind nearly 30 years ago, ION has a long list of features setting it apart from nearly any other “pintech” product. The bi-directional heel unit alone is enough to cause extreme joy (rotate either direction for touring mode!). Add the boot toe location system for your tech-virgin friend, along with what may be supreme durability, and yes it can.

Oh, and don’t forget the cosmetics. Industrial design is important. Things should look good and finished when you’re using them for an aesthetic activity such as ski touring. With its anodized aluminum parts and nicely molded plastic, ION has a completed appearance that’ll have you enjoying just looking at it — at least when your eyes are not drawn to the sublime alps this equipment is allowing you to enjoy.

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.