Disclaimer: By using these mounting instructions and templates, you agree to not hold Wildsnow.com, its owners or associates liable for anything. There is no warranty for these instructions, and no support. You are on your own. These are instructions for mounting an antique binding for display, this binding is NOT RECOMMENDED for skiing or field use as it does not have the safety release of modern ski bindings. If you choose to ski on this binding, you do so at your own risk and agree not to hold Wildsnow.com, its owners or associates liable for anything.

Silvretta 404 ski touring binding, it came in several color schemes.

Backcountry skiing bindings based on the “plate” design, such as the Silvretta 404 model series, are easy to mount. Take care to locate the binding in the correct for/aft position on the ski, be sure the binding is centered left/right, position the heel unit correctly — and you’re good to go.

To mount your Silvretta 404 backcountry skiing bindings, follow the directions below and use our carefully designed mounting template you can download here.

(Warning: After downloading and printing template, compare to screw hole patterns on actual binding, as printing can sometimes distort the layout. If it doesn’t match, tweak printer settings such as scaling, which should be set to 100% or possibly “no scaling.”)

What I’m presenting here is one of many ways a craftsman could achieve a good binding mount that’s authentic and will look good in a collection display. If you’re comfortable with tools and measurements, you’ll probably figure out a few variations along the way. Whatever you do, remember the idea is to center the bindings left/right on the ski, and locate the boot so it matches the boot location mark on the ski.

First, you need a good workbench or kitchen counter. Cover your counter with something liked taped butcher paper or cardboard. Tools and materials needed:

— handheld screwdriver with pozidriv bit to fit screws that come with the binding (with care you can use a jumbo philips bit, but pozi is much better, see note at bottom of this page.)

– electric drill with sharp 5/32 inch bit or special ski binding bit (see note at bottom of page)

– electrical tape and clear office tape, and of course some duct tape

– sharp center-punch, with associated hammer

– long straight steel or aluminum ruler (wooden yardstick is not straight enough)

– tape measure

– fine point Sharpie type marker

– 1-hour epoxy or other preferred binding screw glue

– paper templates

– scissors and paper punch

Step 1 Locate the mounting mark (aka “sole midpoint”) on your boots. It’s usually a small vertical line, arrow, or triangle molded into the side of the sole midway between heel and toe. If your boot doesn’t have midpoint mark just locate it by measurement. Enhance the mark with your Sharpie so you can’t miss it.

Step 2 Find the boot mounting mark on the skis; usually a small triangle, arrow or line that’s at the approximate midpoint of where you’d imagine a boot would sit on the ski.

Be sure you get the right mark — if in doubt ask a shop rat, or contact the ski manufacturer. Enhance the ski mark by using a straightedge to draw a mark completly across the ski (left-right).

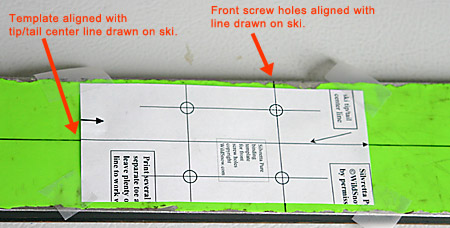

Use your long steel ruler to mark a tip/tail center line that extends well beyond front and back of binding. You’ll use this mark to align paper templates, so make it perfect!

Step 3 Continue doing layout marks. This time, make a nice long tip/tail center mark on both skis. THIS IS IMPORTANT, as our whole method of mounting depends on these marks being accurate. Measure across the ski (or use folded paper) to make left/right center marks a few inches ahead and behind the actual binding location. Connect the marks with your long steel ruler, then ink a nice long tip/tail center line on top of the ski. You’ll use this mark to align the paper templates. Do it well! Mark the tip/tail center line well beyond front and back of binding. You’ll use this mark to align paper templates, so make it perfect!

Step 4 Grab a Silvretta 404 backcountry skiing binding, adjust it for your boot, then snap boot into binding.

Step 5 Set the binding/boot combo on a ski, and align the mounting mark on the boot over that on the ski. I usually eyeball this. If in doubt, make a small square out of cardboard and use it to reach up from the ski to the mark on the boot. Again, take care that you get this exact to the nearest millimeter or so.

Step 5 On top of the ski, near the edge, carefully mark the for/aft location of the binding’s front screw holes. You’ll use this mark to line up the paper template. The idea here is to locate the screw holes in terms of their distance from the tip and tail of the ski, you’ll use the paper template to align them left-right.

Step 7 Enhance the the marks you made for the screw hole locations by using a straightedge to draw left-right marks on the ski top.

Front portion of paper template on ski (template shown is not for 404). Template has been cut so it’s slightly narrower than ski, but long enough to show plenty of the left/right center location line.

Step 8 Cut out the toe portion of the WildSnow paper template, leaving plenty of paper in front and behind screw marks, so you can line up tip/tail center marks accurately. Cut paper from either side of screw holes to make template slightly narrower than ski. Place paper template on ski with center marks aligned, and front screw mark aligned with screw mark/line you drew on ski. Tape template to ski once it’s perfect.

Step 9 Now the first moment of truth. Grab your sharp center punch, and dimple the exact center of the screw marks. Remove the paper template.

Step 10 Chuck that sharp 5/32 bit in your drill. (Using a sharp drill bit prevents the bit from wandering sideways while you drill.) Place a screw in the binding (with the plastic shoe that goes under the toe unit) as if it were already in the ski, and use the protruding screw as a gauge to to figure how deep you will drill. Tape a depth stop to the bit by wrapping tightly with electrical tape to create the stop. Drill your center punch marks with minimal pressure, so you don’t mash the bit through a ski.

(If you do totally klutz it and drill through a ski, it’s actually not that big a deal (repair with epoxy and P-tex), but it’s considered poor style — to say the least — and is none too good for your kitchen countertop. By the way, if you got the brakes for the bindings, put them on after you’ve done the mount, as they make it harder to work with the bindings.)

Step 11 Screw the binding to the ski using the front screws. Torque with care as not to strip the screw hole (don’t use a power drill to torque screws unless you’re a tool ace). Start by gently tightening one screw, then check how the rear of the plate lines up with your tip/tail centerline. Continue to tighten screws will checking alignment. Sight down through the screw holes in the binding and first place screws in holes that align best with holes in ski. If you’re confident about your mount, place epoxy in the screw holes before inserting screws. Otherwise, do a “dry mount” first and only gently tighten screws. Once you’re sure you’ve got it right, pull the screws, then re-insert with epoxy.

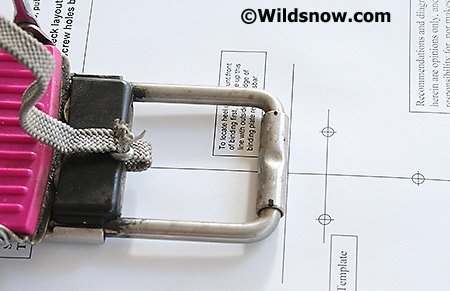

Step 12 With the 404 plate/frame mounted on the ski, centered and in correct for/aft location, it’s now time to mount the binding heel unit. Go slow, locating this properly is critical. Cut out the heel section from a paper template, leaving plenty of the tip/tail center line. Lift the plate, place the paper template under the rear of the plate, then lower the plate. Move the paper template to align the indicated mark with the rear of the plate. Center the template using the tip/tail line, then tape it to the ski.

Locate rear template by lining up with rear of binding frame/plate as shown here. To do so, use a corner of a square piece of paper or cardboard, set edge of this on on template and use as square to get the line in the exact spot.

Step 13 Check location of heel unit by lifting the plate, placing the heel unit on the ski with latch in open position, then drop the plate so it sets down in the heel latch. Be sure the resulting configuration matches that of the photos. If so, check that the paper template didn’t get moved as you worked, then follow drilling and fastening instructions in steps 9 to 12 above. Done!

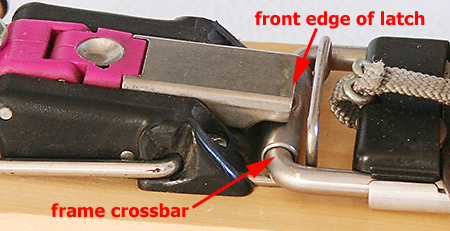

With correctly mounted rear unit, front edge of latch will be located just forward of the center of the frame’s rear crossbar.

With correctly mounted rear unit, front edge of latch will be located just forward of the center of the frame’s rear crossbar. This allows space behind the crossbar for it to move during ski flex. If latch is mounted too far rearward the binding plate-frame can pull out of the catch if the ski is heavily de-cambered. If it’s mounted too far forward the ski will have a stiff spot while flexing because the plate-frame will hit the rear unit.

Note the small concave metal disk visible on the pink plastic of the touring latch. This covers a screw hole, and when pushed down with a ski pole tip the binding easily snaps up and unlatches. If this part is missing you won’t be able to unlatch with a pole tip, and you’ll get quite a bit of snow or water down in the hole, which can corrode the screw or cause the binding to ice up. If you don’t have the metal disc, at least cover this hole with some duct tape.

The disk easily pops out of the hole when levered up with a small pointed object such as an awl.

Drill bits: Ski shops use special drill bits for drilling skis, usually 4.1 mm diameter for skis with metal layers, and 3.5 mm for skis without metal. If you mount a lot of backcountry skis, it’s a good idea to buy a selection of special drill bits from an outfit such as SlideWright. Along with such bits, buy a threading tool (tap) to thread the holes. In my experience, it’s okay to use the slightly larger 5/32 inch (3.9) mm) drill bit as suggested above, without a tap. If you do so, especially with non-metal skis, just be careful as you twist the screws in so you don’t over-tighten them and strip the holes, and use 1-hour epoxy in the holes since they’re slightly oversized. With skis that have a soft core and minimal binding mount reinforcement you can use the slightly smaller 9/64 inch (3.5 mm) drill bit size which is quite close to the standard ski drill size of 3.6 mm. To remove epoxied screws, lightly heat with soldering iron before twisting out, don’t use 5 minute epoxy as it’s brittle. Pozi screwdriver bits are also available from SlideWright, and mandatory if you want to do a decent job. Please see our article about ski drill bits.