This week, we’re taking a look at the greener sides of the ski industry. It is of course not lost on us that we’re all sliding around on hunks of plastic and steel, feet entrapped in more plastic and carbon (who knows the carbon fiber footprint of a typical ski? Perhaps fodder for the next green week…), but this week we’re looking at the half-full glass of sustainable innovations and conversations in the ski world.

At WildSnow, we generally agree on the importance of eco-friendly products in the ski industry and their relevance in a global setting. That is, it’s great to make steps in a more sustainable direction provided the performance and cost are reasonable. Ski touring gear and maintenance is such an infinitesimally small part of our global sustainability and carbon production issues. If every skier ditched fluorocarbon waxes and purchased carbon offsets for their ski trips, we wouldn’t even move the needle on carbon output worldwide.

We can however inspire change through our passionate powder pursuits. I feel that the ski world’s most effective and helpful role is providing voice and leadership to the global problem. So do what you can within your backcountry travels and don’t beat up anyone else for not doing the same, is at least my personal opinion. Off the soapbox, into the wax box.

Back in September, Lou teased the release of Mountain Flow Eco wax, made just down the road from Wildsnow HQ in Carbondale, Colorado. I was able to get my hands on some of the all temperature prototype last spring, and have been using a retail version of the same variety this winter.

About the wax

Due to a pending patent, MountainFlow founder Peter Arlein is unable to divulge exact contents of the wax. He assured us that we would be the first to know once he is able to do so. We can report that they succeeded in creating a 100% plant based hot wax, including hydrophobic slip additives, using a combination of plant waxes and oils. As noted in our September article, there is a bit of soy product included, but less than other plant wax products. Arlein found that soy was too soft in larger quantities.

Pricing

MountainFlow hot wax comes in warm, cool, cold, and all temp varieties. A 4.6 oz chunk of MountainFlow wax retails for $18.50. At roughly $4 per ounce, it is quite competitive with other brands. Often time the consumer must “vote with their wallet” and pay up for green products. A bit of google window shopping and rough math reveals these competitor’s cost expressed in USD/oz (sorry international readers, the $/g or kg were confusingly small or large for my tiny American brain).

$5.60/oz Purl plant based

$1.75/oz Purl original

$16/oz Swix flourocarbon

$6/oz Swix hydrocarbon

This puts MountainFlow on the middle-to-low end of the price spectrum, which is appealing providing that it goes on easily and glides well. This meets my first criteria for adoption of an alternative product. How about the application and performance?

Application

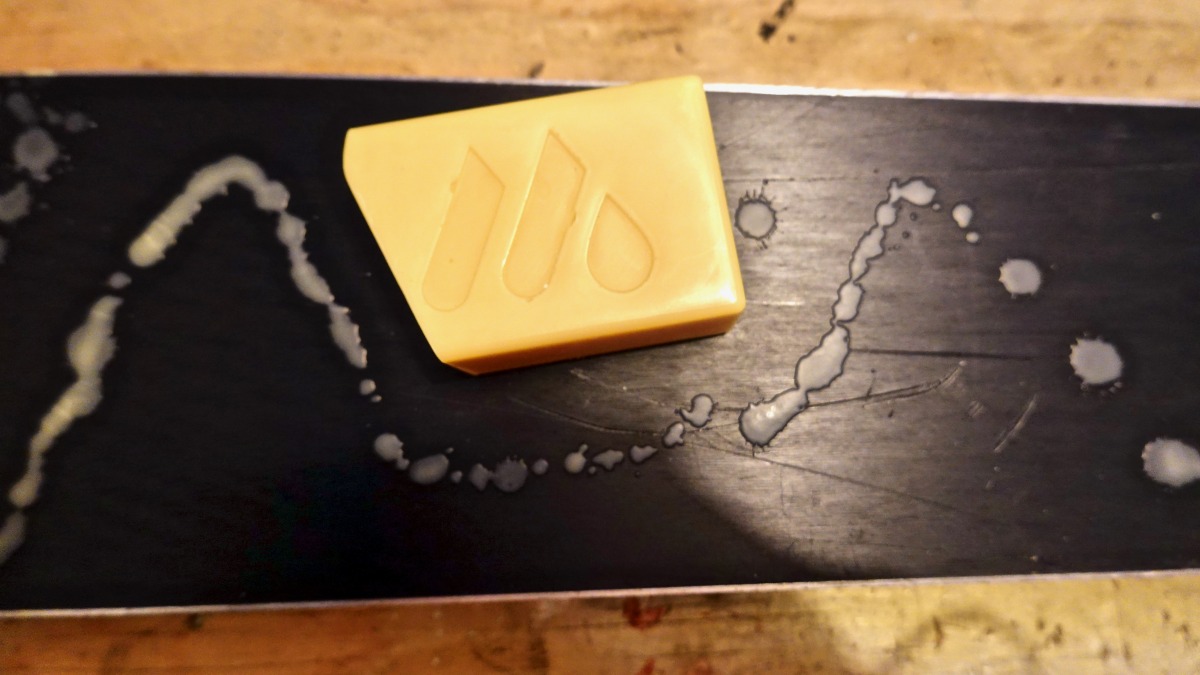

Applying MountainFlow is the same process as applying any petroleum based wax. Heat iron to 115 degrees F (recommended setting for the all-temp model) drizzle on wax, iron wax in to base, scrape and brush base, go skiing, repeat as needed.

The wax smells nice when melting, and is probably better for you to inhale than petroleum-based waxes.

In practice, it is quite similar to standard waxes, though there is a noticeable ‘gummy’ or sticky property to it. This was a deterrent on my first application, gumming up the scraper and brush. MountainFlow advised an extra sharp scraper, long tip to tail strokes, and continual cleaning of the tools. A dull scraper will cause friction and heat up the wax causing that gummy feel. The sharp scraper helped indeed, as most wax aficionados would have done to begin with. Eco Wax will require a bit more cleaning of your brushes and scraper sharpness, but regardless of a little extra tool maintenance, application is the same as a standard petroleum and paraffin based waxes.

Performance

Dropping in to the Holy Cross Couloir last spring. Ski bases gliding well with Mountain Flow on cold powder up top to corn on the southerly apron.

I’m a moderate-to-low waxer in the never-to-daily spectrum we see in the backcountry world, applying about every 2-3 days in spring, as compared to 2-3 weeks in winter. I wax mainly for skin glue health and ease of exits on long, flat egresses in wet snow. Springtime melt-freeze snow, often littered with bits of nature, can really take a toll on wax. Additionally, those long egresses in wet snow tend to be a daily occurrence, and my shoulders and arms are thankful for any break from nordic poling that a fresh coat of wax provides.

I was impressed with the longevity of MountainFlow last spring, pushing beyond that 3-day threshold on occasion. Performance in various wet snow conditions (hot-pow to overcooked corn) was excellent too. Skin glue did not peel off any wax or behave any differently on the ski. All in all, a success.

I ironed on my first coat this season the night before a cold tour. Temperatures were hovering right around 8 degrees F, the minimum listed temperature for the all-temp variety. I expected to feel the sharp cold dendrites piercing the wax and slowing my roll a bit. To my delight, I was able to glide with ease and enjoy deep powder laps one after the other. I have yet to re-apply to that ski, and it is still gliding well after a couple of weeks.

Former racers or serious wax nerds may notice a difference between Mountain Flow and a top notch Fluorocarbon wax. Mountain Flow has that audience in mind though. They are currently developing a race wax to compete with the on snow performance of these environmentally unfriendly waxes.

It is refreshing that hard work, ingenuity and industry — keystones that brought us the gear revolution we are enjoying now — are developing eco-friendly alternatives to some necessary products. Regarding that hard work, Arlein says “There was a lot of trial and error. The R&D process took about 200 formulations before we got it dialed. That meant that we got to do a lot of skiing (“product testing”) so no complaints!”

Why not use plants to lube up your petroleum-based plastic bases and clean it off edges made of steel from unregulated factories in China? Maybe a movement such as MountainFlow’s can inspire changes to the way the rest of our gear is made? Stay tuned this week for a look at Checkerspot, a materials company turned ski maker that is using an innovative replacement for petrol based core and sidewall materials which is, unlike fossil fuel derivatives, more tunable for ski performance.

Want to give it a try? Shop for it.

On March 22nd 2021, Gary Smith tragically died in an avalanche outside of Beaver Creek Resort in Colorado. Since 2018, Gary has been a frequent and insightful contributor to WildSnow. From Christmas Eve spent at the Wildsnow Field HQ cabin, to testing gear and sharing his love for steep skiing around the world, he was a pillar of the ski touring community and will be greatly missed.