Using Tech Crampon 250 while booting a couloir in the Torres Del Paine area in southern Chile. click all images to enlarge.

I’m at a trade show a while back. Guide and author Martin Volken pulls me aside and says he has a top-secret product to show me. Cloak-and-dagger style, he pulls a tiny bundle of steel spikes out of his bag. At first I thought they were ski crampons. Not even close. He attached the Tech Crampon 250 to the toe of a nearby Dynafit boot, and thus created a solid little miniature crampon. I was impressed with the simplicity and ingenuity of the system.

When I first saw the Tech Crampon 250, inventor Manfred Quaeck had been perfecting them for several years. Since then I’ve seen them go through several incremental improvements (something I’m pretty familiar with in my profession as an industrial designer). I tested an older version all last winter, and have been using the current, production version during my summer ski trip to South America.

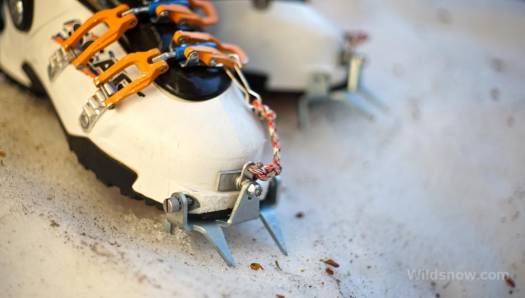

Tech Crampon 250 is fairly simple. They are manufactured out of a single piece of laser cut steel with several small fittings. As opposed to a normal 10 point crampon, these have two front points, and two on either side for a total of 6. They have two threaded pins on either side that fit into the tech fittings of a tech compatible boot, and attach the crampon to a boot. On the front of the crampon is another screw that is used to adjust the crampon for variances in boot shapes. The crampons also come with a short leash that can be clipped to the front of the boot.

Because ski boot models have a variety of specific toe shapes, the crampons must be set up for a specific boot before they can be used. This involves loosening the front screw and adding or removing washers so that it fits to the toe. Setting them up took me a bit of fiddling, but is fairly simple and easy. Once set up, the crampons are put on your boot by tightening a single screw on one side of the crampon. I usually tighten the screw with my fingers, and then get it even tighter by using something handy as a makeshift screwdriver. Most often I just use the clip that is on the leash of the crampons.

At first glance, the tiny “techpons,” much like the tech binding system they are based on, don’t inspire much confidence. However, with further inspection you’ll notice the connection feels solid. I’ve used the techpons for quite a few long ascents, on everything from deep powder to hard neve. They have proven to work quite well.

Of course the main advantage is that they pack up into a package smaller than an orange, and only weigh 240 grams. Compared to a full steel crampon, that’s a significant weight and space savings. Especially since it seems that 80% of the time I carry crampons they’re only used as ballast in the bottom of my pack. It’s easy to justify throwing in the little Tech Crampon pouch when there is a possibility that crampons might be necessary (a constant reality in South America, and in the spring in the Northern Hemisphere).

I’m also a big fan of steel crampons. Steel spikes can be relied on fully if ice is encountered, and won’t dull or get damaged as readily if you happen to walk over some rocks. The Tech Crampons are steel, so although they are light and small, they pack a surprising punch when it comes to real climbing. (Weight fanatics note that with a different grade of steel the techpons could be made somewhat lighter, but they’re so light compared to regular crampons that’s probably a non issue.)

While front-pointing, I’ve grown to trust Tech crampon 250 as much as my normal crampons. Also, the fact that they don’t have rear spikes make wallowing in deep snow a bit easier, since there is less of a chance of the crampons catching on your pant cuffs. However, on long climbs on steep hard snow I do prefer to traverse, and use the side of my foot. Since the Tech Crampons don’t have many side points they make side-hilling tricky and take some getting used to.

The crampons are also surprisingly easy to put on, more so than traditional crampons. With a bit of practice, they can be attached with one hand, without bending over.

The Tech Crampons attached to my Scarpa Maestrale RS boots. The leash is attached to the front buckle, and you can see the attachment screw which is located on the anterior side of each boot.

The little crampons are sharp. A traditional crampon bag is much too big, so I made a simple, light one out of a soda bottle and some duct tape.

Of course, these minuscule crampons do have some necessary compromises when compared to standard full size steel crampons. As I mentioned previously, the lack of rear points can make booting up sideways a little tricky. I’ve found that I easily get used to it, and haven’t encountered a situation where I would rather have my full crampons instead. However, I can imagine for a long day of mostly cramponing (such as a late-summer ski of one of the steeper Cascade volcano routes), a pair of heavier, traditional crampons might be more efficient as the human calf muscle can only take so much. Also, the crampons don’t have any sort of anti-balling plate, and I’ve experienced some snow sticking to the steel every once in a while. I’m planning on experimenting with a simple home-made anti-balling plate, but the techpon really should be sold with an OEM anti-balling solution.

Also, the crampons are built out of thick, burly steel. Steel is reliable, and I prefer it most of the time. However, for the ultimate in lightweight crampons, it would be cool to see an aluminum version of the tech crampons.

The bottom side of the crampons. As you can see, the exposed rubber and steel is a little prone to balling up.

It’s worth mentioning that Tech Crampon 250 has only recently began retail sales, so they haven’t been tested by a large number of people. Nonetheless I’ve tested two versions; both held up well. The older prototype I tested for several months, and the newer production version has gotten even more use after a month in Patagonia. While they’re not a full-on ice climbing solution and require judgment on when they’re appropriate, Tech Crampon 250 is a solid solution for a lighter and smaller backpack.

Louie Dawson earned his Bachelor Degree in Industrial Design from Western Washington University in 2014. When he’s not skiing Mount Baker or somewhere equally as snowy, he’s thinking about new products to make ski mountaineering more fun and safe.